The Check Engine Light glaring at you from your dashboard is never a welcome sight. When it decides to make an appearance, your car is trying to tell you something’s amiss. One of the culprits behind this automotive distress signal could be the cryptic OBD2 code P0335. This code signals a problem with your vehicle’s crankshaft position sensor circuit – a critical component for engine performance.

But what does this code mean, and more importantly, how do you fix it? This comprehensive guide will delve into the intricacies of the OBD2 code P0335, explaining its causes, symptoms, diagnostic procedures, and potential solutions.

Understanding the Crankshaft Position Sensor and its Importance

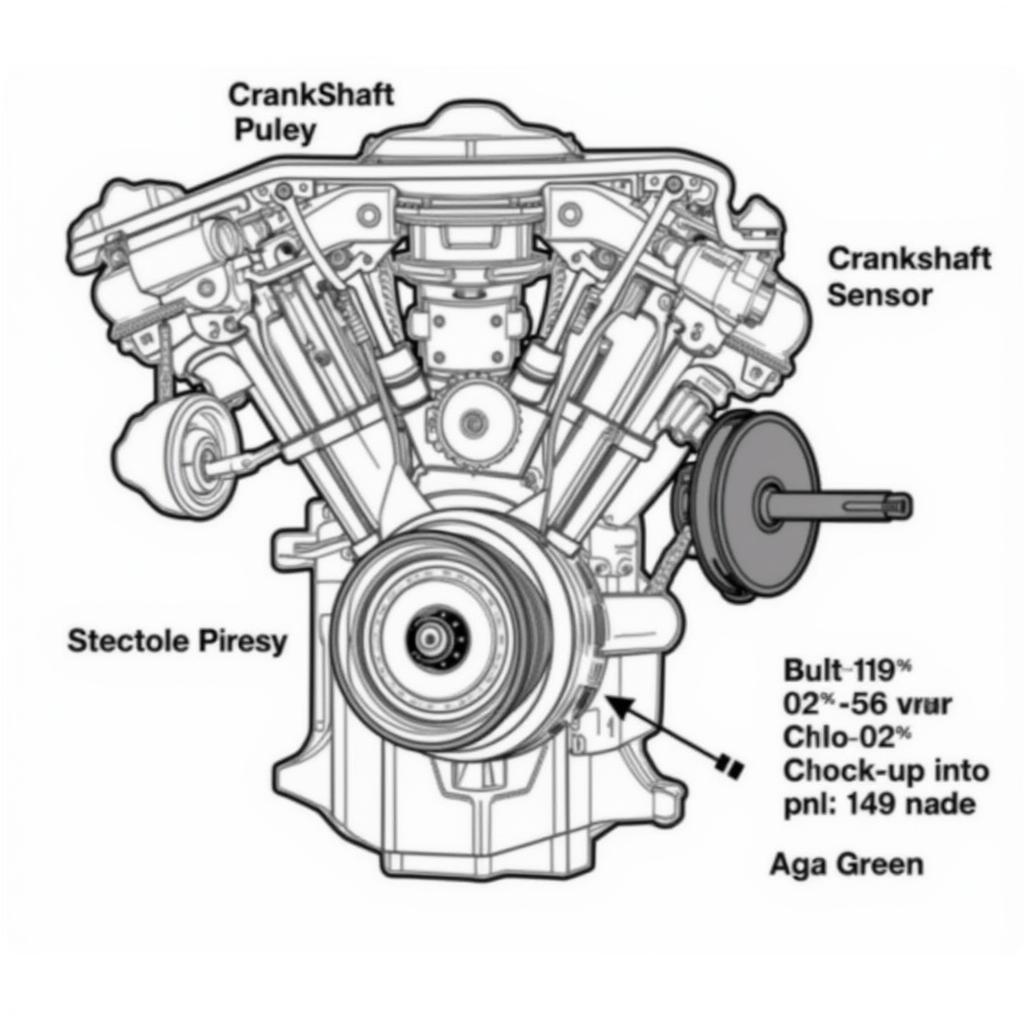

Before we tackle the P0335 code head-on, let’s understand the role of the crankshaft position sensor (CKP) in your vehicle’s operation. The CKP sensor is a magnetic component typically located near the crankshaft pulley or flywheel. Its primary function is to monitor the crankshaft’s rotational speed and position. This information is crucial for the engine control unit (ECU) to manage essential functions like:

- Fuel Injection Timing: The ECU relies on CKP sensor data to determine the precise moment to inject fuel into the cylinders for optimal combustion.

- Ignition Timing: The CKP sensor helps the ECU determine the exact timing to fire the spark plugs, ensuring efficient ignition of the air-fuel mixture.

Deciphering the OBD2 Code P0335

The OBD2 code P0335 specifically indicates a problem with the crankshaft position sensor “A” circuit. The “A” typically refers to a specific sensor or circuit location, as some vehicles may have multiple crankshaft position sensors. This code means the ECU is not receiving the correct signal from the CKP sensor circuit, hindering its ability to manage engine functions effectively.

Common Causes of the P0335 Code

Several factors can disrupt the crankshaft position sensor circuit, triggering the P0335 code. Some of the most common causes include:

- Faulty Crankshaft Position Sensor: Like any electrical component, the CKP sensor itself can wear out or fail over time. Exposure to extreme temperatures, vibrations, and engine fluids can contribute to its demise.

- Damaged Wiring or Connectors: The wiring harness connecting the CKP sensor to the ECU is susceptible to damage from heat, corrosion, or abrasion. Loose or corroded connectors can also disrupt the signal flow.

- Damaged Crankshaft Pulley or Reluctor Ring: The crankshaft pulley often has a toothed reluctor ring that the CKP sensor uses to detect the crankshaft’s position. Damage to either the pulley or the reluctor ring can disrupt the signal.

- ECU Problems: While less common, a malfunctioning ECU can also cause communication issues with the CKP sensor circuit, triggering the P0335 code.

Recognizing the Symptoms of a P0335 Code

A malfunctioning crankshaft position sensor circuit can manifest in various ways, impacting your vehicle’s performance and drivability. Keep an eye out for these telltale signs:

- Illuminated Check Engine Light: The most obvious symptom is the illumination of your vehicle’s check engine light, alerting you to a potential problem with the engine management system.

- Engine Stalling: The engine may stall frequently, especially when idling or coming to a stop. This happens because the ECU lacks the necessary information from the CKP sensor to maintain a stable idle.

- Difficulty Starting: Starting the engine might become difficult or impossible, as the ECU cannot determine the crankshaft’s position to initiate fuel injection and ignition.

- Reduced Engine Performance: You might experience a noticeable decrease in engine power, acceleration, and overall performance due to improper fuel delivery and ignition timing.

- Increased Fuel Consumption: The engine may consume more fuel than usual as the ECU tries to compensate for the lack of accurate sensor data, leading to inefficient combustion.

Diagnosing the P0335 Code

If your vehicle exhibits any of the symptoms mentioned above, it’s crucial to diagnose the problem promptly. Here’s a step-by-step approach to help you identify the root cause of the P0335 code:

- Retrieve the OBD2 Code: Use an OBD2 scanner to read the diagnostic trouble codes stored in your vehicle’s ECU. The scanner will display the P0335 code if there is a problem with the crankshaft position sensor circuit.

- Visually Inspect the CKP Sensor and Wiring: Begin by visually inspecting the CKP sensor for any visible damage, such as cracks, loose connections, or corrosion. Examine the wiring harness for any signs of fraying, burns, or cuts.

- Test the CKP Sensor: Use a digital multimeter to test the sensor’s resistance and voltage. Compare your readings to the manufacturer’s specifications to determine if the sensor is functioning within the acceptable range.

- Check for Continuity: Check for continuity in the wiring harness between the CKP sensor and the ECU using the multimeter. This will help you identify any breaks or shorts in the wiring.

- Inspect the Crankshaft Pulley and Reluctor Ring: Examine the crankshaft pulley for any damage or misalignment. Inspect the reluctor ring for any missing or damaged teeth, which can disrupt the sensor’s signal.

- Consider ECU Testing: If all other components check out, the ECU itself may be faulty. However, ECU testing and repair require specialized equipment and expertise, so it’s best to consult a qualified mechanic.

Potential Solutions for the P0335 Code

Once you’ve identified the underlying cause of the P0335 code, you can proceed with the necessary repairs. Here are the most common solutions for this code:

- Replace the Crankshaft Position Sensor: If the sensor is faulty, replacement is the most effective solution. Ensure you use a high-quality replacement sensor that meets your vehicle’s specifications.

- Repair or Replace Damaged Wiring: If you find any damaged wiring or connectors, repair or replace them as needed. Use heat shrink tubing or electrical tape to protect the repaired sections.

- Replace the Crankshaft Pulley or Reluctor Ring: If the pulley or reluctor ring is damaged, replacement is necessary. Ensure the new components are properly aligned during installation.

- Consult a Qualified Mechanic for ECU Repair: If the ECU is suspected to be faulty, it’s crucial to consult a qualified mechanic with experience in ECU diagnostics and repair.

Addressing Frequently Asked Questions About the P0335 Code

Can I drive my car with a P0335 code?

While you might be able to drive a short distance with a P0335 code, it’s not recommended. Driving with a faulty crankshaft position sensor circuit can lead to further engine damage and potentially leave you stranded.

How much does it cost to fix a P0335 code?

The cost of repair varies depending on the underlying cause and your vehicle’s make and model. Replacing a faulty crankshaft position sensor can cost between $150 to $300, while more extensive repairs, such as replacing the ECU, can cost significantly more.

Can a bad crankshaft position sensor cause other problems?

Yes, a malfunctioning crankshaft position sensor can lead to other engine-related issues, such as misfires, reduced fuel economy, and increased emissions.

Need More Help?

If you’re experiencing issues with your car’s OBD2 system, particularly the P0335 code, don’t hesitate to reach out to our team of experts. We’re here to assist you 24/7. Contact us via WhatsApp at +1(641)206-8880 or email us at [email protected]. We’re dedicated to providing you with the guidance and support you need to get your vehicle back on the road safely and efficiently.

For additional information and insights into various OBD2 codes and automotive diagnostics, explore our extensive collection of articles and resources on our website.