The OBD2 connector PCB, short for On-Board Diagnostics connector Printed Circuit Board, is the unsung hero of vehicle diagnostics. It’s the physical interface that allows your OBD2 scanner to communicate with your car’s computer, unlocking a treasure trove of information about your vehicle’s health and performance. But what exactly is an OBD2 connector PCB, and how does it work its magic?

Decoding the OBD2 Connector PCB

Imagine the OBD2 connector PCB as a translator between two people speaking different languages. Your car’s computer speaks in a language of voltage signals, while your OBD2 scanner understands digital data. The OBD2 connector PCB bridges this gap, converting the signals from your car into data your scanner can interpret.

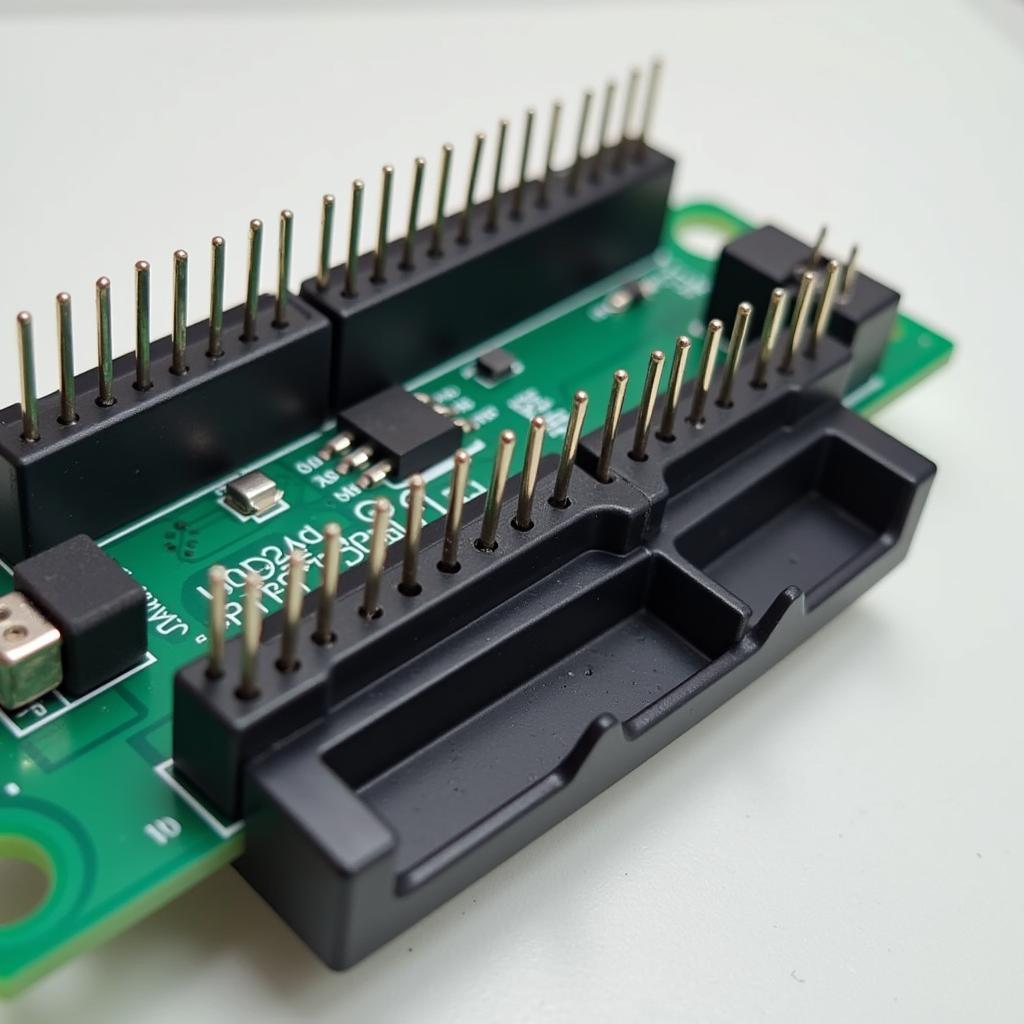

This translation process happens through the 16 pins on the OBD2 connector. Each pin is assigned a specific function, ranging from transmitting data to providing power to the scanner. The arrangement and function of these pins are standardized across all OBD2-compliant vehicles, ensuring compatibility with a wide range of scanners.

The Importance of a High-Quality OBD2 Connector PCB

A reliable OBD2 connector PCB is crucial for accurate and efficient vehicle diagnostics. A faulty PCB can lead to communication errors, inaccurate readings, and even damage to your scanner or car’s computer.

Factors that can affect the quality of an OBD2 connector PCB include:

- Material Quality: A high-quality PCB uses durable materials that can withstand heat, vibration, and corrosion.

- Manufacturing Precision: Precise manufacturing ensures that the pins are properly aligned and spaced, preventing connection issues.

- Soldering Quality: Strong and clean solder joints are essential for reliable electrical connections.

Choosing the Right OBD2 Connector PCB

While you won’t typically buy an OBD2 connector PCB separately, understanding its importance can help you choose a high-quality OBD2 scanner. When selecting a scanner, look for:

- Reputable brands: Choose scanners from established manufacturers known for their quality and reliability.

- Durable construction: Opt for scanners with robust connectors and housings that can withstand regular use.

- Positive user reviews: Check online reviews and forums for feedback on the scanner’s performance and durability.

Investing in a high-quality OBD2 scanner with a reliable connector PCB ensures accurate diagnostics, saving you time, money, and potential headaches down the road.

Frequently Asked Questions About OBD2 Connector PCBs

What happens if my OBD2 connector PCB is damaged?

A damaged OBD2 connector PCB can lead to communication errors between your scanner and your vehicle. This can result in inaccurate readings, inability to connect to the vehicle’s computer, or even damage to your scanner or car’s systems.

Can I replace a damaged OBD2 connector PCB myself?

While replacing an OBD2 connector PCB is possible, it’s not recommended unless you have experience with electronics repair. It’s best to consult a qualified mechanic or electrician for assistance.

How do I maintain my OBD2 connector PCB?

To maintain your OBD2 connector PCB, keep the connector clean and free of debris. Avoid forcing the connector in or out of the port, and ensure that the scanner is properly connected before powering it on.

Explore More About OBD2

For a deeper dive into the world of OBD2 diagnostics, check out our comprehensive obd2 course. This course covers everything from understanding OBD2 codes to using advanced scanning techniques.

Remember, a well-maintained OBD2 connector PCB is your key to unlocking your vehicle’s secrets and ensuring its optimal performance.

Need help with your OBD2 scanner or vehicle diagnostics? Contact us via WhatsApp at +1(641)206-8880 or email us at [email protected]. Our dedicated customer support team is available 24/7 to assist you.