The evolution of engine management systems brought about the transition from OBD1 to OBD2, leading to questions about compatibility, especially regarding the use of an “obd1 harness on obd2 engine”. While a simple plug-and-play solution isn’t feasible due to fundamental differences between the two systems, achieving functionality with modifications is possible. This article delves into the intricacies of OBD1 and OBD2 systems, exploring the challenges and providing insights into making this conversion work.

Understanding the OBD1 and OBD2 Divide

Before diving into the conversion, it’s crucial to understand the key differences between OBD1 and OBD2 systems:

- Diagnostics: OBD1 relies on rudimentary diagnostic capabilities, often requiring manufacturer-specific tools and procedures. OBD2, on the other hand, standardizes diagnostics, enabling generic OBD2 scanners to retrieve comprehensive engine data.

- Sensors and Actuators: OBD2 systems utilize a wider range of sensors to monitor various engine parameters, ensuring optimal performance and reduced emissions. This difference in sensor technology poses a significant challenge when adapting an OBD1 harness to an OBD2 engine.

- Communication Protocols: OBD1 communication protocols are proprietary to each manufacturer, while OBD2 employs a standardized communication protocol (SAE J1850 or CAN) for universal compatibility.

Challenges of Using an OBD1 Harness on an OBD2 Engine

The fundamental differences between OBD1 and OBD2 systems present several challenges:

- Incompatible Connectors: The physical connectors of OBD1 and OBD2 harnesses differ, making a direct connection impossible.

- Missing Sensors: OBD2 engines require inputs from sensors that are absent in OBD1 systems, such as dedicated camshaft and crankshaft position sensors, leading to inaccurate engine data and potential performance issues.

- Communication Breakdown: The contrasting communication protocols make it impossible for an OBD1 system to interpret data from an OBD2 engine.

Making the Conversion Work

While daunting, adapting an OBD1 harness for use with an OBD2 engine is achievable with modifications:

- Harness Adaptation: You’ll need to create a custom wiring harness or modify the existing OBD1 harness to accommodate the additional sensors required by the OBD2 engine. This involves meticulous wiring, ensuring each sensor connects to the appropriate pin on the ECU.

- ECU Compatibility: Using the original OBD1 ECU with an OBD2 engine is typically not feasible. You might explore using a standalone engine management system (EMS) that allows for custom tuning and sensor configuration.

- Sensor Integration: Sourcing and installing the missing sensors, such as the crankshaft position sensor and camshaft position sensor, is crucial for accurate engine operation.

- Exhaust Considerations: OBD2 systems incorporate more sophisticated emissions control systems. You might need to adapt or upgrade your exhaust system to meet emission standards.

“Adapting an older OBD1 system to a newer OBD2 engine requires careful consideration of the sensor requirements, wiring modifications, and potential ECU compatibility issues,” says John Miller, a veteran automotive electronics engineer. “A successful conversion demands a thorough understanding of both systems and meticulous attention to detail.”

Is It Worth the Effort?

Converting an OBD1 harness for use with an OBD2 engine is a complex undertaking, demanding significant electrical and mechanical expertise. It often involves sourcing parts, custom fabrication, and extensive troubleshooting.

When might this conversion be considered:

- Engine Swaps in Classic Cars: Enthusiasts swapping newer OBD2 engines into classic cars with OBD1 systems might opt for this route.

- Limited Budget Constraints: In specific scenarios, converting an existing harness might seem more cost-effective than purchasing a standalone EMS.

However, it’s crucial to weigh the challenges and costs against the benefits. In many cases, using a standalone EMS, while a greater initial investment, often proves more straightforward and reliable in the long run.

Alternatives to Consider

Before embarking on the complex journey of harness conversion, explore these alternatives:

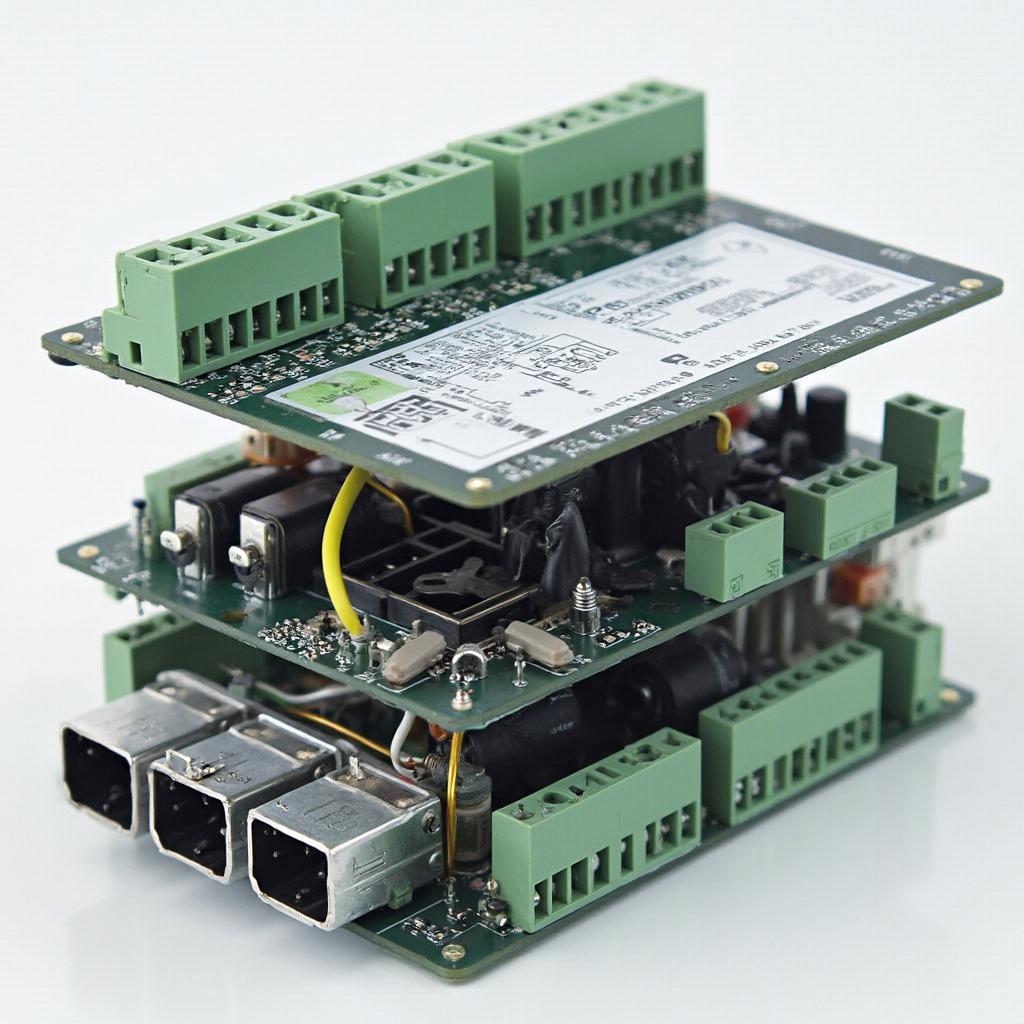

- Standalone Engine Management System (EMS): A standalone EMS offers greater flexibility and control over engine parameters, making it an attractive alternative for modified or swapped engines.

- OBD2 Engine with OBD1 ECU Compatibility: Certain aftermarket ECUs are designed to work with both OBD1 and OBD2 systems, offering a potentially simpler solution.

Standalone Engine Management System (EMS)

Standalone Engine Management System (EMS)

Conclusion

Successfully using an “obd1 harness on obd2 engine” requires overcoming significant compatibility hurdles. While achievable with modifications, the complexity and potential for issues might outweigh the benefits in many situations. Exploring alternative solutions like a standalone EMS or seeking guidance from experienced professionals is often advisable.

FAQs

Can I simply plug an OBD1 harness into an OBD2 engine?

No, the connectors and communication protocols are incompatible, making a direct plug-and-play impossible.

What are the main challenges of this conversion?

Key challenges include incompatible connectors, missing sensors required by the OBD2 engine, and differing communication protocols.

Is this conversion recommended for all vehicle owners?

No, this conversion is best suited for experienced individuals or professionals comfortable with complex electrical systems.

What are some alternatives to consider?

Consider using a standalone EMS or exploring aftermarket ECUs compatible with both OBD1 and OBD2 systems.

Where can I find additional resources and information?

For specific guidance related to your vehicle and conversion needs, consider exploring resources on obd1 engine harness obd2 car, h22a obd1 to obd2, or consulting with our team of experts.

Need Assistance?

If you need guidance with OBD2 diagnostics, engine swaps, or understanding your vehicle’s systems, contact us. Our team of automotive experts is here to provide personalized support and answer your questions. Reach out via WhatsApp at +1(641)206-8880 or email us at [email protected]. We offer 24/7 customer support.