The OBD2 VTEC engine harness is a critical component in modern Honda vehicles equipped with Variable Valve Timing and Lift Electronic Control (VTEC). This system allows the engine to switch between different camshaft profiles to optimize performance and fuel economy. The harness itself acts as the central nervous system, relaying vital information and commands between the engine control unit (ECU) and the VTEC system.

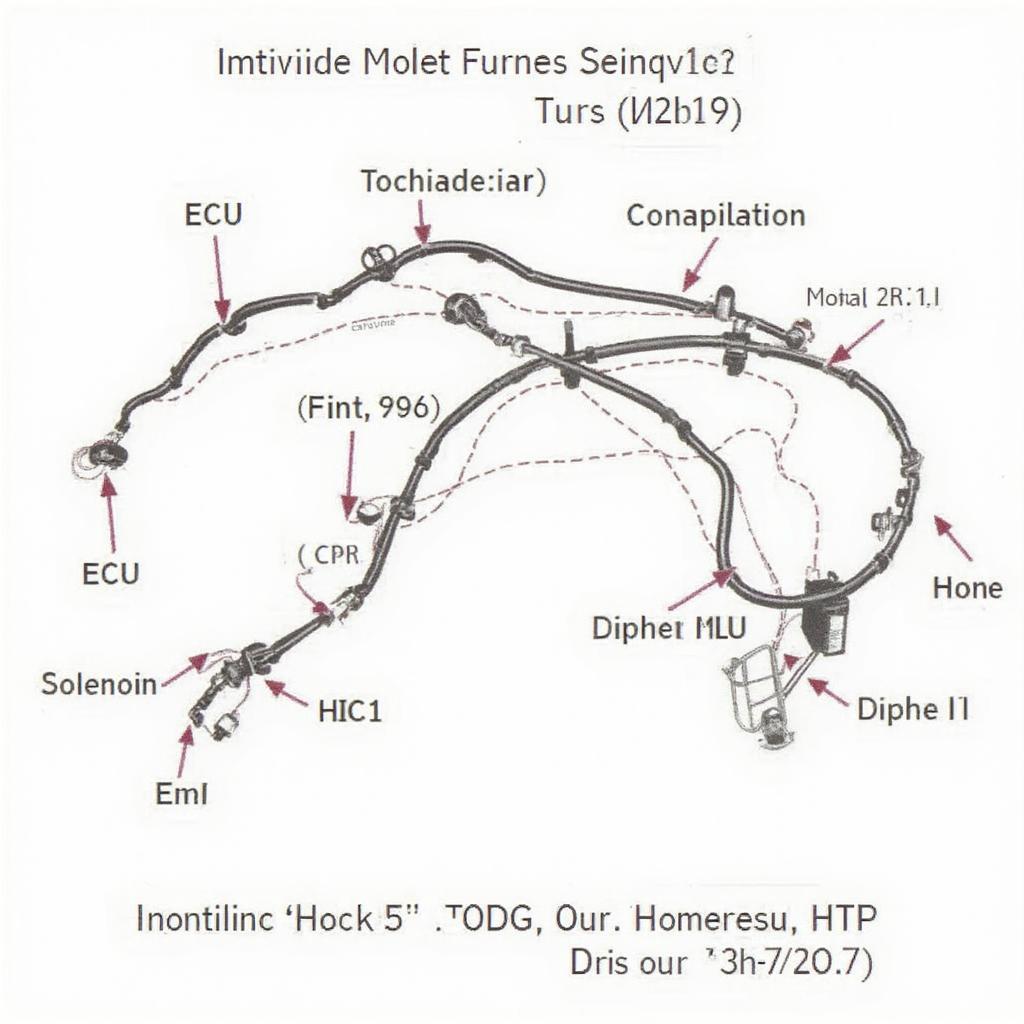

OBD2 VTEC engine harness diagram

OBD2 VTEC engine harness diagram

Decoding the OBD2 VTEC Engine Harness

The OBD2 VTEC engine harness comprises a network of wires and connectors designed to withstand the harsh conditions under the hood. Its primary functions include:

- Signal Transmission: The harness carries signals from various sensors, such as the crankshaft position sensor and camshaft position sensor, to the ECU. This data is crucial for the ECU to determine the engine’s speed, load, and position, allowing it to make informed decisions about VTEC engagement.

- VTEC Solenoid Control: The ECU sends commands through the harness to activate or deactivate the VTEC solenoid. This solenoid, in turn, controls the flow of oil that engages the high-performance camshaft profile.

- Power Distribution: The harness supplies power to essential components within the VTEC system, ensuring their proper operation.

A malfunctioning OBD2 VTEC engine harness can lead to a range of issues, including:

- Erratic VTEC Engagement: Intermittent or complete loss of VTEC functionality.

- Check Engine Light Illumination: Diagnostic trouble codes (DTCs) related to VTEC system malfunctions stored in the ECU’s memory.

- Poor Engine Performance: Reduced power, hesitation, or rough idling.

Common Causes of OBD2 VTEC Engine Harness Problems

- Wear and Tear: Over time, exposure to heat, vibration, and engine fluids can degrade the harness’s insulation and connectors.

- Oil Contamination: Leaks from engine components like the valve cover gasket can allow oil to seep into the harness, causing corrosion and short circuits.

- Rodent Damage: Rodents are known to chew on wiring harnesses, leading to open circuits and electrical malfunctions.

Troubleshooting OBD2 VTEC Engine Harness Issues

Diagnosing and repairing an OBD2 VTEC engine harness requires specialized knowledge and tools. Here are some steps involved in the process:

- Visual Inspection: Carefully examine the harness for any visible signs of damage, such as cuts, abrasions, or loose connections.

- Diagnostic Scanning: Connect an OBD2 scanner to retrieve stored DTCs, which can provide valuable clues about the harness’s condition.

- Continuity and Resistance Testing: Using a multimeter, test the continuity of individual wires and the resistance of the circuits to identify open or shorted connections.

Conclusion

The OBD2 VTEC engine harness plays a vital role in ensuring the optimal performance and efficiency of Honda’s VTEC system. Regular inspection and timely repair of any harness issues are crucial to prevent potential engine problems and maintain a smooth driving experience. If you suspect an issue with your OBD2 VTEC engine harness, seeking professional diagnosis and repair is highly recommended.

FAQs

-

Can I drive with a faulty OBD2 VTEC engine harness?

Driving with a damaged harness can lead to further damage and potentially dangerous driving conditions. It’s best to address the issue promptly. -

How much does it cost to replace an OBD2 VTEC engine harness?

The cost varies depending on the make and model of your vehicle and labor rates. It’s best to consult with a qualified mechanic for an accurate estimate. -

Can I replace the OBD2 VTEC engine harness myself?

While possible, it’s a complex repair that requires advanced mechanical skills and specialized tools. It’s generally recommended to have a professional handle the replacement.

Need help with your OBD2 VTEC Engine Harness? Contact us on WhatsApp: +1(641)206-8880, Email: [email protected]. Our team is available 24/7 to assist you!