A broken engine mount can turn a smooth ride into a bumpy, noisy experience. But beyond the discomfort, it can lead to more severe engine damage if left unaddressed. This article delves into everything you need to know about OBD2 codes related to a broken engine mount, equipping you with the knowledge to diagnose and fix the issue.

Can an OBD2 Scanner Detect a Broken Engine Mount?

Here’s the tricky part: an OBD2 scanner cannot directly detect a broken engine mount. Engine mounts are mechanical components, and a standard OBD2 scanner primarily focuses on the electronic systems within your vehicle.

However, a broken engine mount often leads to other issues that do trigger OBD2 codes. These codes can act as valuable clues, pointing you towards a potential engine mount problem.

Symptoms of a Broken Engine Mount

While an OBD2 scanner might not directly flag a broken engine mount, your car will likely exhibit some telltale signs, including:

- Excessive Engine Vibration: The most obvious symptom is unusual vibrations, especially when accelerating, decelerating, or idling.

- Clunking or Banging Noises: You might hear these noises from the engine bay, particularly during gear shifts or when driving over bumps.

- Misaligned Engine: In severe cases, a broken engine mount can cause the engine to visibly shift its position in the engine bay.

- Engine Movement: Open the hood and observe the engine while someone else revs it in neutral. Excessive movement can indicate a broken mount.

Diagnosing the Problem

If you suspect a broken engine mount, here’s a step-by-step guide:

- Visual Inspection: Carefully examine the engine mounts for any visible cracks, tears, or separation of the rubber.

- Check for Engine Movement: As mentioned earlier, have someone rev the engine while you observe it for excessive movement.

- OBD2 Scan: Even though it won’t directly identify a broken mount, scan for any other codes that might be related to engine performance or misfires, as these could be indirect indicators.

Using an OBD2 Scanner as a Supporting Tool

While an OBD2 scanner might not be the primary tool for diagnosing a broken engine mount, it can still provide helpful information:

-

Misfire Codes: A broken engine mount can disrupt the alignment of engine components, potentially leading to misfires. Look for codes like P0300 (random misfire) or specific cylinder misfire codes (e.g., P0301 for cylinder 1).

-

Other Performance Codes: Codes related to engine performance, like those for oxygen sensors or the mass airflow sensor, might be indirectly triggered by the engine’s altered position due to a broken mount.

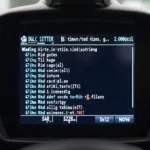

A mechanic connecting an OBD2 scanner to a car's diagnostic port, illustrating its use in diagnosing engine-related issues

A mechanic connecting an OBD2 scanner to a car's diagnostic port, illustrating its use in diagnosing engine-related issues

“It’s crucial to remember that OBD2 codes offer clues, not definitive diagnoses,” says automotive expert Jake Carter. “Always correlate the codes with physical symptoms and a thorough inspection to get a complete picture.”

Fixing a Broken Engine Mount

Replacing a broken engine mount is typically a job for a mechanic. It involves:

- Safely Securing the Engine: Mechanics use specialized equipment to support the engine while removing the broken mount.

- Removing the Old Mount: This involves unbolting the mount from both the engine and the chassis.

- Installing the New Mount: The new mount is carefully aligned and bolted into place.

Preventing Future Engine Mount Problems

- Regular Inspections: Include a visual check of your engine mounts during routine maintenance.

- Addressing Engine Issues Promptly: Issues like excessive engine vibration or misfires can strain engine mounts, so address them quickly.

- Quality Parts: When replacing mounts, opt for high-quality parts from reputable manufacturers for durability.

FAQs

Q: How much does it cost to replace an engine mount?

A: The cost varies depending on your car model and labor rates. On average, expect to pay between $200 and $500.

Q: Can I drive with a broken engine mount?

A: It’s not recommended. Driving with a broken mount can cause further damage to other engine components and pose a safety risk.

Conclusion

While an OBD2 scanner might not directly diagnose a broken engine mount, it can provide valuable supporting information. By recognizing the symptoms, understanding the potential related OBD2 codes, and performing a thorough inspection, you can effectively diagnose and address this issue, ensuring a smooth and safe driving experience.

If you’re looking for a reliable OBD2 scanner to help you diagnose other potential car problems, consider checking out these options:

- BlueDriver LSB2 Pro OBD2 ACAN Tool: This professional-grade scanner offers in-depth diagnostics and a user-friendly interface.

- Bosch ProGrade OBD2 Scan Tool: Known for its quality and reliability, the Bosch ProGrade scanner is a solid choice for DIYers and professionals alike.

Remember, early detection and repair are key to preventing further damage and costly repairs down the road.