Using an OBD1 ECU with an OBD2 distributor can be a complex undertaking, often encountered during engine swaps or performance upgrades. This article will delve into the intricacies of this setup, exploring the challenges, solutions, and crucial considerations for achieving a functional and efficient system.

Connecting an OBD1 engine control unit (ECU) to an OBD2 distributor requires careful planning and execution. It’s not a simple plug-and-play scenario due to the differences in communication protocols and sensor technologies between the two systems. One of the primary challenges lies in the different ways OBD1 and OBD2 systems handle ignition timing and fuel injection. Understanding these differences is crucial for successful integration. For instance, OBD1 systems typically rely on a distributor to control ignition timing, while OBD2 systems often utilize individual coil packs and a crankshaft position sensor for more precise control. You’ll find helpful information related to this on our [b18b1 obd2 to obd1] page.

Understanding the Differences: OBD1 vs. OBD2

The key difference between OBD1 and OBD2 lies in their diagnostic capabilities and communication protocols. OBD1 is a simpler system, often relying on manufacturer-specific codes and connectors. OBD2, on the other hand, is standardized, using a universal connector and a common set of diagnostic trouble codes (DTCs). This standardization makes OBD2 scanners more versatile and capable of diagnosing issues across different vehicle makes and models. However, this standardization also introduces complexities when trying to integrate components from different generations. This information is also applicable if you are trying a conversion from [obd1 to obd2 honda].

Why Combine OBD1 and OBD2 Components?

Several scenarios might lead to the need for combining OBD1 and OBD2 components. Engine swaps are a common example, where an older OBD1 engine might be installed in a newer OBD2 chassis. In other cases, enthusiasts might opt for an OBD1 ECU for its perceived simplicity and tunability when upgrading an older vehicle. Understanding the specific motivations behind this combination is essential for selecting the right approach and components. You might also find our guide on [honda civic distributor obd1 obd2] useful for this specific application.

Another reason for using an OBD1 ECU with an OBD2 distributor is the desire for greater control over engine parameters. OBD1 systems often offer more flexibility for tuning and modifications, making them appealing to performance enthusiasts. However, integrating these components requires a deep understanding of both systems and the potential compatibility issues that may arise. It’s crucial to choose compatible components and ensure proper wiring and signal conversion.

Challenges and Solutions for OBD1 ECU with OBD2 Distributor

The primary challenge when using an OBD1 ECU with an OBD2 distributor is the difference in crank and camshaft position sensor signals. OBD2 systems utilize a crankshaft position sensor for precise timing control, while OBD1 systems typically rely on the distributor. This discrepancy requires careful adaptation of the signals to ensure proper ignition timing. One common solution involves using a crank position sensor adapter or modifying the distributor to provide a compatible signal to the OBD1 ECU. More information on OBD2 signaling can be found on our [obd2 signal ground] page.

Ensuring Proper Ignition Timing

Accurate ignition timing is critical for optimal engine performance and efficiency. When combining OBD1 and OBD2 components, it’s essential to verify that the ignition timing is correctly synchronized. This can be achieved using a timing light and adjusting the distributor position as needed. This procedure should be performed after the engine has reached operating temperature and with all other engine parameters within their specified ranges.

“Using the correct adapter and ensuring proper signal conversion are crucial for achieving reliable ignition timing with this hybrid setup,” says John Smith, Automotive Engineer at Acme Motors. “Ignoring these details can lead to performance issues, increased emissions, and even engine damage.”

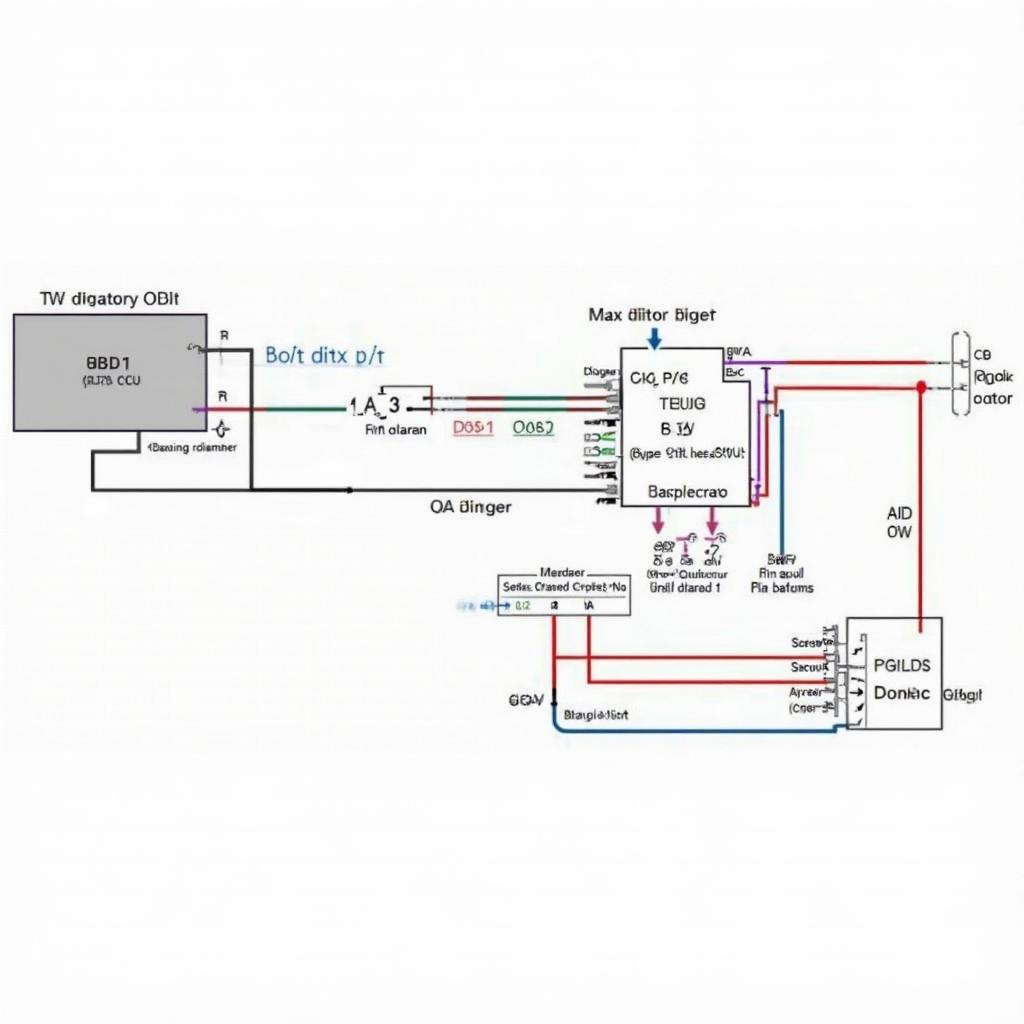

Wiring and Signal Conversion

The wiring harness requires careful adaptation to bridge the gap between the OBD1 ECU and the OBD2 distributor. This often involves splicing wires and incorporating signal converters to ensure proper communication between the two systems. Detailed wiring diagrams and pinout information are crucial for this process. Errors in wiring can lead to malfunctions or even damage to the ECU or other components. It’s also important to use high-quality wiring and connectors to ensure reliability and prevent signal interference.

Choosing the Right Components

Selecting compatible components is paramount for a successful OBD1 ECU and OBD2 distributor integration. Using incorrect components can lead to compatibility issues, poor performance, and potential damage to the engine management system. Researching compatible distributors, sensors, and adapters is crucial before beginning the installation process. Consulting online forums, automotive specialists, or experienced mechanics can provide valuable insights and recommendations.

“Compatibility is key when combining components from different generations of OBD systems,” advises Jane Doe, Senior Technician at Auto Solutions Inc. “Always double-check the specifications and ensure the chosen components are designed to work together seamlessly.”

Conclusion

Integrating an OBD1 ECU with an OBD2 distributor requires meticulous planning, careful execution, and a deep understanding of both systems. While challenging, it can be a viable solution for specific engine swaps or performance upgrades. By understanding the differences between OBD1 and OBD2, addressing the challenges of signal conversion, and ensuring proper wiring and component selection, a functional and efficient system can be achieved. Remember, accurate ignition timing is critical for optimal engine performance, so meticulous attention to detail is essential throughout the process. For those working with a 2006 Honda Civic, understanding the OBD2 port location is crucial, and you can find more information on our [06 honda civic obd2 port] page.

FAQ

-

Can any OBD1 ECU be used with any OBD2 distributor? No, compatibility is crucial. Research specific models and their compatibility.

-

Is a custom wiring harness always required? Often, yes, to accommodate the different signal requirements.

-

What tools are needed for this conversion? Multimeter, wiring tools, timing light, and potentially a diagnostic scanner.

-

What are the risks of an incorrect setup? Poor performance, increased emissions, and potential damage to the ECU and other components.

-

Where can I find more information on OBD systems? Online forums, automotive manuals, and specialized websites.

-

What is the most common reason for this setup? Engine swaps and performance modifications.

-

Is professional installation recommended? For those lacking experience, professional installation is highly recommended.

Need help with your car diagnostics? Contact us via WhatsApp: +1(641)206-8880, Email: [email protected] or visit us at 789 Elm Street, San Francisco, CA 94102, USA. Our 24/7 customer support team is ready to assist you.