A camshaft position sensor, or cam sensor, is vital for engine timing. Understanding cam sensor OBD2 wave forms is crucial for diagnosing engine performance issues. These waveforms, viewed through an obd2 oscilloscope, offer valuable insights into the sensor’s operation and potential problems.

Decoding the Cam Sensor Signal

The cam sensor generates a specific wave pattern, which the OBD2 scanner translates into usable data. This data helps determine the engine’s timing and adjust fuel injection and ignition accordingly. Analyzing these waveforms can pinpoint issues like a faulty sensor, wiring problems, or even mechanical timing problems within the engine.

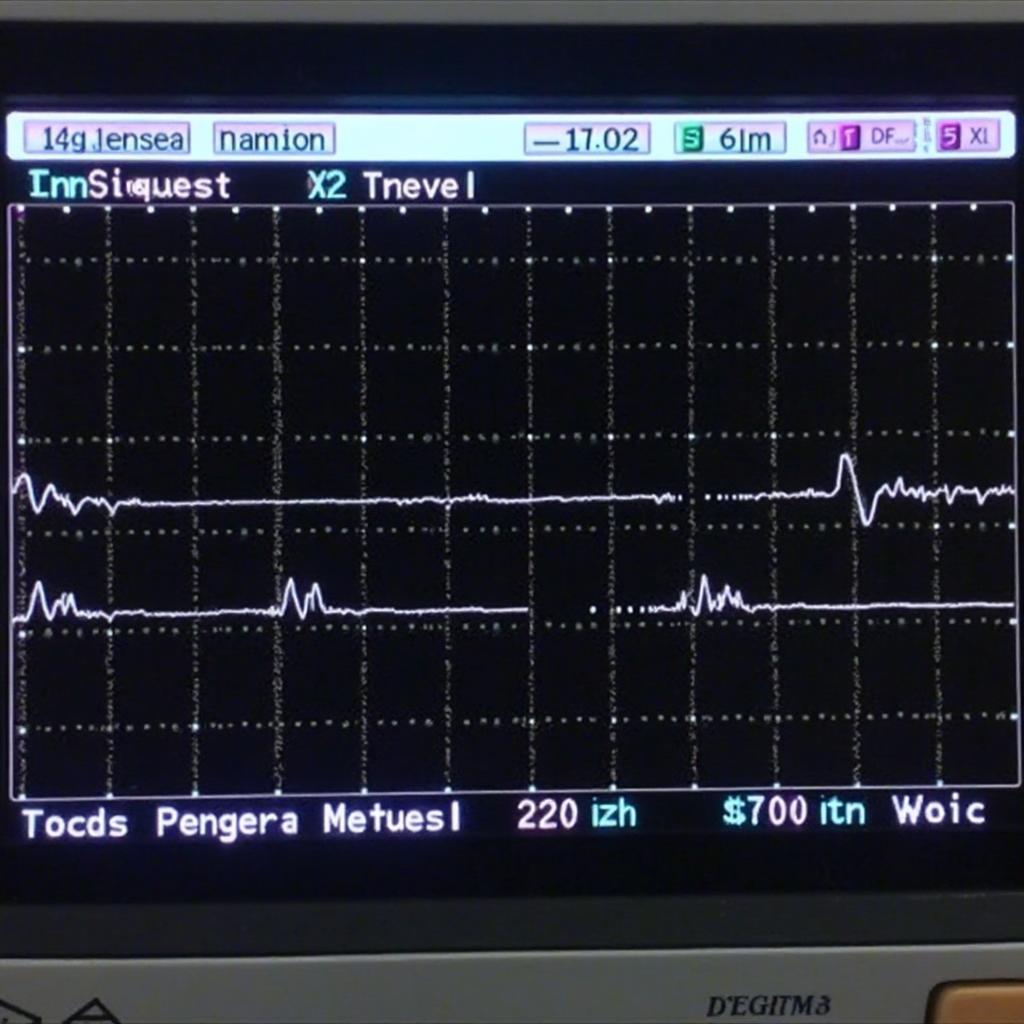

A healthy cam sensor waveform usually resembles a square wave, with distinct high and low voltage levels. However, variations can exist depending on the specific engine and sensor type. The frequency and amplitude of the wave are directly related to the engine speed and camshaft position.

Common Cam Sensor Waveform Issues

Several irregularities in the waveform can indicate problems:

- Missing Teeth: Gaps or inconsistencies in the square wave can suggest a damaged or worn reluctor wheel on the camshaft.

- Low Amplitude: A weak signal, indicated by a lower than expected voltage, could point to a failing cam sensor, poor wiring connections, or excessive resistance in the circuit.

- Noise: Erratic fluctuations or spikes in the waveform could signify electrical interference, often caused by a damaged wire or a poor ground connection.

- No Signal: The absence of a waveform suggests a completely failed cam sensor, a broken wire, or a problem with the sensor’s power supply.

Understanding these anomalies can help mechanics pinpoint the root cause of the problem and avoid unnecessary part replacements.

Using an OBD2 Oscilloscope to Analyze Cam Sensor Waveforms

An obd2 oscilloscope is essential for visualizing cam sensor waveforms. Connecting the oscilloscope to the appropriate sensor circuit allows you to observe the signal in real-time. This real-time analysis is crucial for identifying intermittent issues that might not be detected by a standard code reader.

Step-by-Step Guide to Analyzing Cam Sensor Waveforms with an OBD2 Oscilloscope:

- Locate the cam sensor wiring connector.

- Connect the oscilloscope probes to the appropriate signal and ground wires.

- Start the engine and observe the waveform on the oscilloscope screen.

- Compare the observed waveform to the manufacturer’s specifications.

- Look for any of the common waveform irregularities discussed earlier.

David Miller, a seasoned automotive diagnostician, emphasizes the importance of understanding these waveforms: “Knowing how to interpret a cam sensor waveform can save you hours of diagnostic time and prevent misdiagnosis. It’s like having a direct window into the sensor’s operation.”

Diagnosing Related OBD2 Codes

Certain OBD2 codes can be directly related to cam sensor issues. For example, the obd2 code po340 often indicates a problem with the camshaft position sensor circuit. By analyzing the cam sensor waveform in conjunction with the trouble codes, you can quickly narrow down the potential causes.

Understanding the protocol obd2 used by your vehicle is also important. Different protocols handle data transmission differently, which can affect the waveform display on the oscilloscope.

Sarah Johnson, an automotive electronics expert, adds, “The OBD2 system provides a wealth of information beyond just trouble codes. Learning to interpret the data from sensors like the camshaft position sensor can significantly enhance your diagnostic capabilities.”

Conclusion

Understanding cam sensor OBD2 wave forms is essential for effective engine diagnostics. By using an OBD2 oscilloscope and interpreting the waveforms correctly, mechanics can accurately identify cam sensor and related issues, leading to faster repairs and improved vehicle performance.

FAQs

- What does a cam sensor do? It tells the engine control unit the position of the camshaft, crucial for timing fuel injection and ignition.

- What tools do I need to analyze cam sensor waveforms? An OBD2 oscilloscope.

- What does a normal cam sensor waveform look like? Typically a square wave.

- What can cause a low amplitude cam sensor waveform? A failing sensor, bad wiring, or high resistance.

- What does noise on a cam sensor waveform indicate? Electrical interference.

- How can I fix a cam sensor problem? The solution depends on the specific issue, which may involve sensor replacement, wiring repair, or even addressing mechanical timing issues.

- What are some common OBD2 codes related to cam sensor problems? P0340 is a common example.

Need further assistance? Contact us via WhatsApp: +1(641)206-8880, Email: [email protected] or visit us at 789 Elm Street, San Francisco, CA 94102, USA. Our customer service team is available 24/7.