AEM wideband OBD2 systems offer a significant upgrade for monitoring your vehicle’s air-fuel ratio (AFR). This critical data provides insights into engine performance and efficiency, enabling you to optimize tuning for power, fuel economy, and engine health. This comprehensive guide dives deep into the world of AEM wideband OBD2, covering everything from installation to advanced applications.

Understanding the Importance of AEM Wideband OBD2

Why is an accurate AFR reading so vital? It’s the key to unlocking your engine’s full potential. A proper air-fuel mixture ensures complete combustion, maximizing power output while minimizing emissions and fuel consumption. A lean mixture can lead to excessive heat and potential engine damage, while a rich mixture wastes fuel and reduces performance. Traditional narrowband OBD2 sensors lack the precision of AEM wideband sensors, making them unsuitable for performance tuning. An aem wideband sensor obd2 provides real-time, high-resolution AFR data, empowering you to fine-tune your engine for optimal performance.

Choosing the Right AEM Wideband OBD2 System

AEM offers various wideband OBD2 solutions, each with its own features and benefits.  AEM Wideband OBD2 Controller Installation Selecting the right system depends on your specific needs and application. Do you need a simple gauge display or a more advanced system with data logging capabilities? The AEM X-Series wideband controllers, for example, offer unparalleled accuracy and advanced features. aem x series obd2 wideband provides real-time AFR data via a digital gauge or OBD2 output, making them ideal for both street and track use. Consider factors like your vehicle’s make and model, your tuning goals, and your budget when choosing an AEM wideband OBD2 system.

AEM Wideband OBD2 Controller Installation Selecting the right system depends on your specific needs and application. Do you need a simple gauge display or a more advanced system with data logging capabilities? The AEM X-Series wideband controllers, for example, offer unparalleled accuracy and advanced features. aem x series obd2 wideband provides real-time AFR data via a digital gauge or OBD2 output, making them ideal for both street and track use. Consider factors like your vehicle’s make and model, your tuning goals, and your budget when choosing an AEM wideband OBD2 system.

Installing Your AEM Wideband OBD2

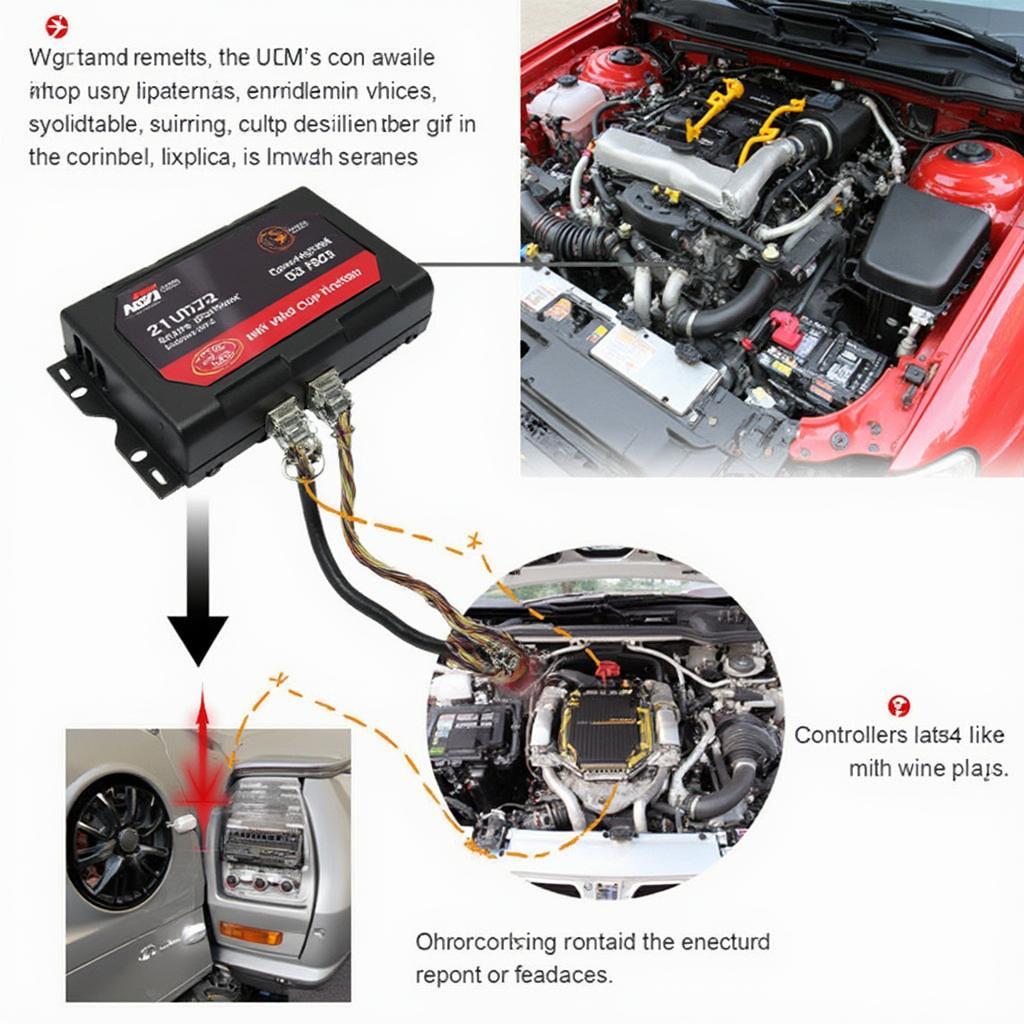

Proper installation is crucial for accurate and reliable AFR readings. Typically, the process involves installing the wideband sensor in the exhaust stream, wiring the controller to the vehicle’s electrical system, and connecting the gauge or display unit. While the installation process is generally straightforward, following the manufacturer’s instructions carefully is essential.

Key Installation Steps:

- Mount the wideband oxygen sensor in the exhaust system.

- Connect the sensor to the AEM wideband controller.

- Wire the controller to the vehicle’s power supply.

- Connect the gauge or display unit to the controller.

- Calibrate the sensor according to the manufacturer’s instructions.

Advanced Applications of AEM Wideband OBD2

Beyond basic AFR monitoring, AEM wideband OBD2 systems can be integrated with other performance tuning tools and data logging software. This allows for in-depth analysis of engine performance and facilitates precise tuning adjustments. using dual aem obd2 widebands can provide even more granular data for high-performance applications. For instance, you can monitor AFR in different parts of the exhaust system or use the data to create custom tuning maps for your engine control unit (ECU).

What are the benefits of dual AEM wideband OBD2 setups?

Dual setups allow for more precise tuning by providing AFR readings from both banks of a V-engine or from before and after a catalytic converter.

“Accurate AFR data is paramount for optimizing engine performance and longevity. AEM wideband OBD2 systems provide the precision and reliability required for achieving your tuning goals,” says renowned automotive engineer, Dr. Emily Carter.

Conclusion: Unleash Your Engine’s Potential with AEM Wideband OBD2

An AEM wideband OBD2 system is an invaluable tool for anyone seeking to maximize their vehicle’s performance and efficiency. From basic AFR monitoring to advanced data logging and tuning applications, aem wideband obd2 empowers you to unlock your engine’s full potential. Invest in an AEM wideband OBD2 system today and experience the difference precise air-fuel monitoring can make. dual aem obd2 widebands provide even further insights for advanced applications.

FAQs

-

What is a wideband OBD2 sensor? A wideband sensor provides a precise and continuous measurement of the air-fuel ratio.

-

Why is a wideband sensor better than a narrowband sensor? Wideband sensors offer significantly greater accuracy and a wider measurement range compared to narrowband sensors.

-

How do I install an AEM wideband OBD2 system? Follow the manufacturer’s instructions carefully. The process typically involves installing the sensor, wiring the controller, and connecting the gauge.

-

Can I use an AEM wideband with my existing tuning software? Many tuning software packages are compatible with AEM wideband systems.

-

What are the benefits of dual wideband sensors? Dual sensors provide more detailed AFR data, particularly for V-engines or when monitoring pre- and post-catalytic converter AFR.

-

Can I use an aem wideband obd2 oil pressure sensor together? Yes, they can be used together to provide a comprehensive view of your engine’s health and performance.

-

Is there a difference between aem wideband sensor obd2 and a regular wideband sensor? The main difference is the integration with the OBD2 system, allowing for easier data logging and monitoring.

For more information on engine diagnostics and OBD2 scanners, explore other articles on our website. Need help choosing the right AEM wideband OBD2 system for your needs? Contact us via WhatsApp: +1(641)206-8880, Email: [email protected] or visit our office at 789 Elm Street, San Francisco, CA 94102, USA. Our 24/7 customer support team is ready to assist you.