The dreaded P0339 OBD2 code indicates a problem with your vehicle’s Crankshaft Position Sensor ‘A’ Circuit, specifically an intermittent issue. This sensor is vital for engine operation, so understanding this code is crucial for getting your car back on the road.

What is the P0339 Code?

The P0339 code signifies an intermittent problem within the crankshaft position sensor ‘A’ circuit. This doesn’t necessarily mean the sensor itself is faulty, but rather that the signal it sends to the Engine Control Unit (ECU) is occasionally disrupted. This disruption can lead to a variety of performance issues, from rough idling to complete engine stalling. A properly functioning crankshaft position sensor tells the ECU the crankshaft’s position and speed, allowing it to control fuel injection and ignition timing accurately.

Symptoms of a P0339 Code

Experiencing any of these symptoms alongside an illuminated check engine light could indicate a P0339 code:

- Rough idling: The engine may idle erratically or vibrate excessively.

- Difficulty starting: The car may crank but struggle to start or not start at all.

- Stalling: The engine may stall unexpectedly while driving or idling.

- Reduced engine performance: You might notice a lack of power or hesitation during acceleration.

- Decreased fuel economy: A malfunctioning sensor can lead to inefficient fuel consumption.

Causes of a P0339 Code

Several factors can contribute to a P0339 code:

- Faulty Crankshaft Position Sensor: While an intermittent issue might not always point to a completely failed sensor, it’s often the primary culprit.

- Wiring Problems: Damaged, corroded, or loose wiring in the sensor circuit can disrupt the signal.

- Connector Issues: A loose or damaged connector can cause intermittent connection problems.

- Damaged Tone Ring: The tone ring, a toothed wheel that the sensor reads, can be damaged, affecting the signal.

- ECU Problems: Although less common, a malfunctioning ECU can also be the source of the problem.

“Intermittent issues can be tricky to diagnose,” says automotive expert Johnathan Smith, ASE Certified Master Technician. “A thorough inspection of the wiring and connector is the first step before replacing the sensor.”

How to Diagnose a P0339 Code

Diagnosing a P0339 code requires a systematic approach:

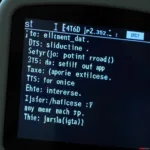

- Retrieve the Code: Use an OBD2 scanner to confirm the P0339 code.

- Visually Inspect: Check the wiring and connector for any visible damage or looseness.

- Test the Sensor: Use a multimeter to test the sensor’s resistance and voltage according to your vehicle’s specifications.

- Check the Tone Ring: Inspect the tone ring for any damage or debris.

- Check the Circuit: Test the circuit for continuity and shorts.

How to Fix a P0339 Code

The specific repair depends on the diagnosed cause:

- Replace the Crankshaft Position Sensor: This is often the most common solution.

- Repair Wiring or Connector: Repair or replace any damaged or corroded wiring or connectors.

- Replace the Tone Ring: If damaged, the tone ring will need replacement.

- Address ECU Issues: If the ECU is faulty, it may require repair or replacement.

honda obd2 crank position sensor bypass prelude

“Don’t underestimate the importance of quality parts when replacing the sensor,” advises Susan Miller, an automotive engineer with over 20 years of experience. “A cheap sensor can lead to further problems down the road.”

p0335 error codes for obd2 2004 dodge ram 1500

Conclusion

The P0339 OBD2 code, indicating a problem with the crankshaft position sensor ‘A’ circuit, can significantly impact your vehicle’s performance. By understanding the causes, symptoms, and diagnostic steps, you can effectively address this issue and restore your car’s smooth running. Don’t hesitate to seek professional help if you’re uncomfortable tackling this repair yourself.

99 beetle crankshaft sensor obd2

Need help with your P0339 code? Contact us via WhatsApp: +1(641)206-8880, Email: [email protected] or visit us at 789 Elm Street, San Francisco, CA 94102, USA. We have a 24/7 customer support team ready to assist you.