Understanding how to convert analog sensors to OBD2 can be incredibly useful for car enthusiasts and professionals alike. This guide will walk you through everything you need to know about integrating analog sensors with your vehicle’s OBD2 system.

What is an Analog Sensor?

Analog sensors are the workhorses of your vehicle’s various systems. They measure physical quantities like temperature, pressure, speed, and position, then translate those measurements into continuous electrical signals. Unlike digital sensors, which transmit data in discrete values (0s and 1s), analog sensors provide a smooth range of voltage or current that corresponds to the measured value.

Why Convert Analog Sensors to OBD2?

Connecting your analog sensors to your OBD2 port opens a world of possibilities:

- Real-time Monitoring: Gain instant access to sensor data directly through your OBD2 scanner or a dedicated display.

- Enhanced Diagnostics: Troubleshooting becomes easier when you can monitor live sensor data and identify anomalies.

- Performance Tuning: Use the data from your sensors to fine-tune your vehicle for optimal performance and efficiency.

- Data Logging: Record sensor data over time to track trends, analyze performance, and diagnose intermittent issues.

How to Convert Analog Sensors to OBD2: Step-by-Step

Converting an analog sensor to OBD2 involves interfacing the sensor’s output with your vehicle’s digital communication network. Here’s a breakdown of the process:

-

Choose the Right Sensor: Ensure the analog sensor you select is compatible with your desired application and provides the necessary measurement range and accuracy.

-

Signal Conditioning: Analog sensor outputs often require conditioning before they can be interpreted by an OBD2 system. This might involve:

- Amplification: Boosting weak signals to usable levels.

- Attenuation: Reducing strong signals to prevent overloading the OBD2 system.

- Filtering: Removing unwanted noise or interference from the signal.

-

Analog-to-Digital Conversion (ADC): An ADC converts the continuous analog signal into a series of digital values that the OBD2 system can understand. The ADC’s resolution and sampling rate are crucial for accurate data representation.

-

Microcontroller Integration: A microcontroller acts as the brain of the operation, processing the digitized sensor data, and formatting it for transmission over the OBD2 protocol.

-

OBD2 Interface: The microcontroller communicates with your vehicle’s OBD2 port using a compatible communication protocol, typically CAN (Controller Area Network) or ISO 9141-2.

-

Display and Analysis: View the sensor data on a compatible OBD2 scanner, a dedicated display unit, or a computer with OBD2 software.

Challenges and Considerations

- Technical Expertise: Converting analog sensors to OBD2 requires a solid understanding of electronics, microcontrollers, and communication protocols.

- Compatibility: Ensure that all components you choose are compatible with each other and your vehicle’s OBD2 system.

- Sensor Calibration: Proper calibration of the analog sensor is critical for accurate readings and reliable data analysis.

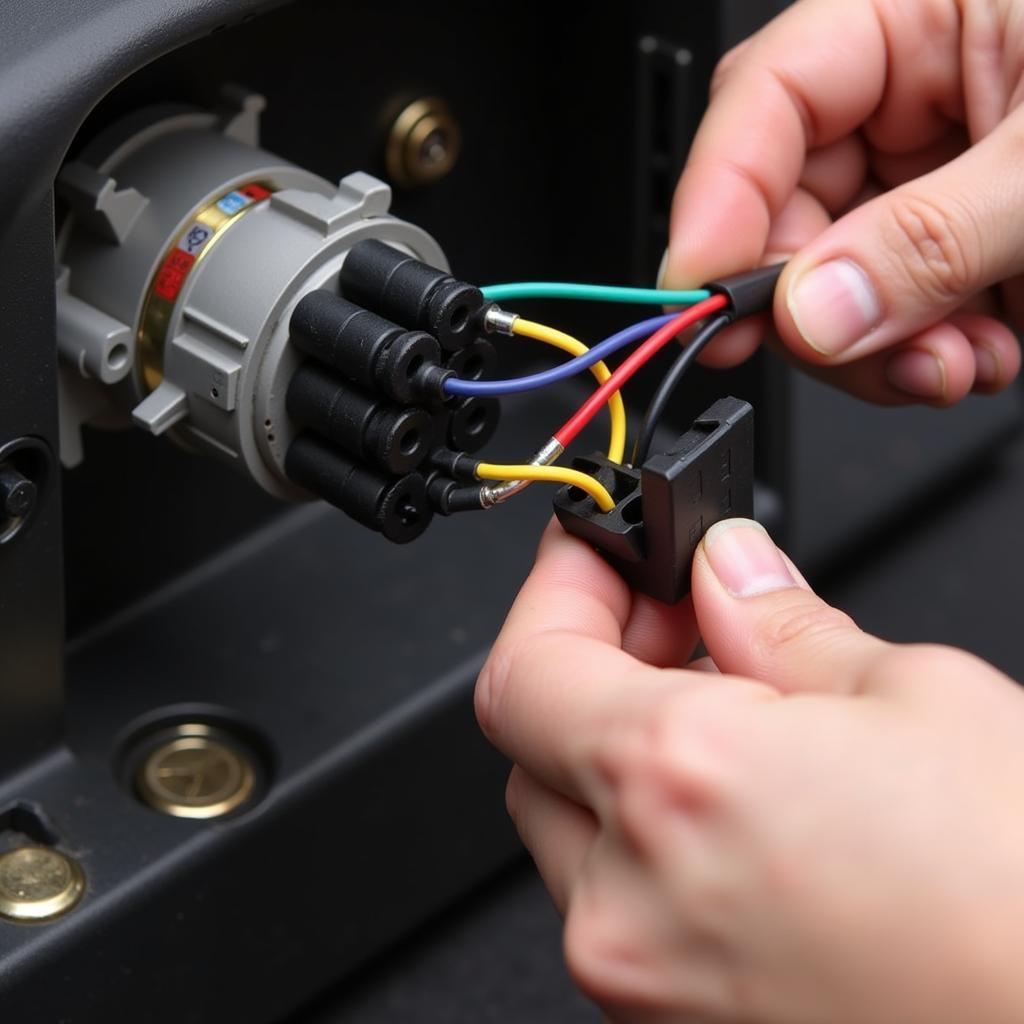

- Wiring and Installation: Accurate and secure wiring is essential for both functionality and safety.

Pre-Built Solutions for Easier Integration

If building your own system from scratch seems daunting, numerous pre-built solutions are available:

- OBD2 Analog Sensor Adapters: These devices simplify the process by providing a plug-and-play solution for connecting common analog sensors like wideband oxygen sensors.

- Aftermarket Engine Management Systems: Some aftermarket engine management systems offer built-in support for connecting analog sensors, providing advanced monitoring and control capabilities.

Conclusion

Converting analog sensors to OBD2 can significantly enhance your ability to monitor, diagnose, and optimize your vehicle’s performance. While the process involves technical considerations, with the right knowledge and resources, you can unlock valuable insights into your vehicle’s inner workings.

Frequently Asked Questions

1. Can I convert any analog sensor to OBD2?

While it’s theoretically possible to convert most analog sensors, some may require specialized circuitry or be impractical due to signal characteristics or safety concerns.

2. What are the common applications for converting analog sensors to OBD2?

Common applications include monitoring boost pressure, wideband air/fuel ratio, oil pressure, and exhaust gas temperature.

3. Do I need programming skills to convert an analog sensor to OBD2?

Depending on the chosen method and complexity, some programming knowledge might be necessary for configuring the microcontroller and communication protocols.

4. Are pre-built OBD2 analog sensor adapters reliable?

Reputable brands offer reliable adapters that simplify the conversion process. Ensure you choose an adapter specifically designed for your sensor type and application.

5. What are the safety precautions when working with vehicle electronics?

Always disconnect the vehicle’s battery before working on any electrical system to prevent shorts or damage. If unsure about any aspect of the process, consult a qualified automotive electrician.

Need help converting an analog sensor to OBD2 or have other car diagnostic questions? Contact our expert team via WhatsApp: +1(641)206-8880, or Email: cardiagtechworkshop@gmail.com. We’re here 24/7 to assist you.