Understanding the intricate workings of your vehicle’s ignition system can seem daunting. Still, a firm grasp of the H23 OBD2 distributor wiring is crucial for any car enthusiast or DIY mechanic. This guide dives deep into the complexities of this system, equipping you with the knowledge to diagnose and potentially fix issues yourself.

Unraveling the H23 OBD2 Distributor

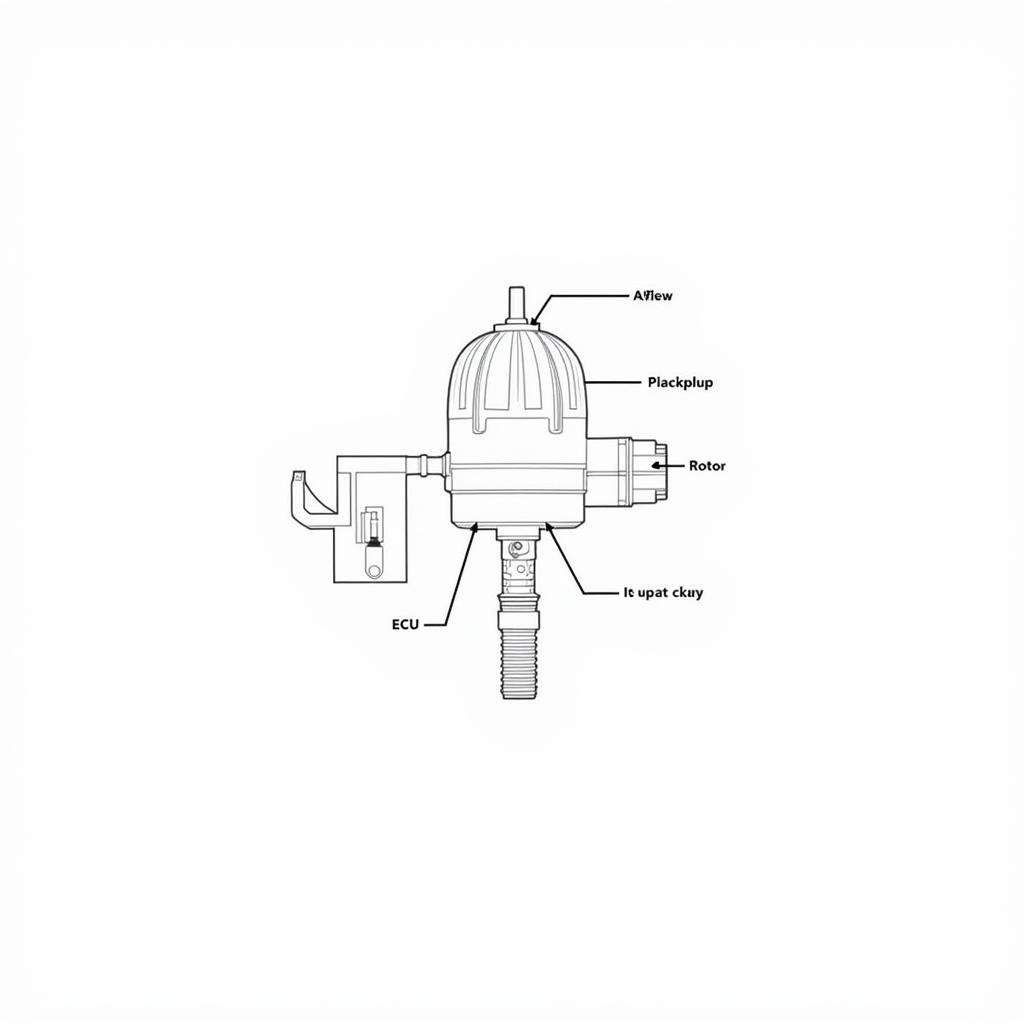

The distributor in your H23 engine plays a vital role in ensuring the smooth operation of your ignition system. It’s responsible for distributing high voltage electricity from the ignition coil to the spark plugs in the correct firing order, igniting the air-fuel mixture in your cylinders and keeping your engine running.

Common H23 Distributor Wiring Issues

While the H23 distributor is generally reliable, several issues can arise with its wiring over time. These include:

- Damaged Wiring: Exposure to heat, oil, and general wear and tear can lead to cracked, frayed, or broken wires, disrupting the flow of electricity.

- Loose Connections: Vibrations from the engine can cause connections at the distributor cap, rotor, or ignition coil to loosen, leading to misfires and poor engine performance.

- Corrosion: Over time, corrosion can build upon terminals and connectors, hindering the electrical flow and causing starting problems or intermittent engine stalls.

Troubleshooting H23 Distributor Wiring

Before diving into the wiring harness, it’s crucial to rule out other potential causes for ignition system issues, such as faulty spark plugs, a bad ignition coil, or a malfunctioning crankshaft position sensor. If these components check out, you can proceed with inspecting the distributor wiring.

Here are some steps for troubleshooting:

- Visual Inspection: Carefully examine all visible wiring and connectors for any signs of damage, looseness, or corrosion. Pay close attention to the distributor cap, rotor, and ignition coil connections.

- Continuity Testing: Using a multimeter, check for continuity in the wiring between the distributor and the ignition coil, as well as between the distributor and each spark plug.

- Resistance Testing: Measure the resistance of the ignition coil and compare it to the manufacturer’s specifications. High resistance can indicate a faulty coil.

Seeking Expert Help

If you’re uncomfortable working on your vehicle’s electrical system or cannot pinpoint the issue, it’s always best to consult a qualified mechanic. They have the expertise and tools to diagnose and repair complex electrical problems safely and effectively.

“A well-maintained ignition system is crucial for optimal engine performance and fuel efficiency,” says John Smith, a seasoned automotive engineer with over 20 years of experience. “Regular inspection and timely replacement of worn-out components can save you from costly repairs down the line.”

Remember, safety is paramount when working with automotive electrical systems. Always disconnect the battery before handling any wiring to avoid electrical shock.

FAQs About H23 OBD2 Distributor Wiring

1. Can I drive with a faulty distributor wiring?

It’s highly discouraged. Driving with a faulty distributor wiring can lead to engine misfires, reduced performance, and potential damage to other ignition system components.

2. How often should I inspect my distributor wiring?

It’s a good practice to inspect your distributor wiring at least once a year or more frequently if you live in an area with extreme temperatures or high humidity.

3. Can I replace the distributor wiring myself?

While it’s possible, replacing distributor wiring requires a good understanding of automotive electrical systems and proper tools.

Need further assistance?

Contact us via WhatsApp: +1(641)206-8880, Email: [email protected]. Our dedicated customer support team is available 24/7 to help.