A home made obd2 reader can be a fascinating project for car enthusiasts and DIYers. This article explores the complexities, benefits, and potential drawbacks of building your own OBD2 diagnostic tool. We’ll delve into the technical aspects, required components, and provide valuable insights for those considering this challenging yet rewarding endeavor. Let’s get started!

Understanding the OBD2 System and Home Made Readers

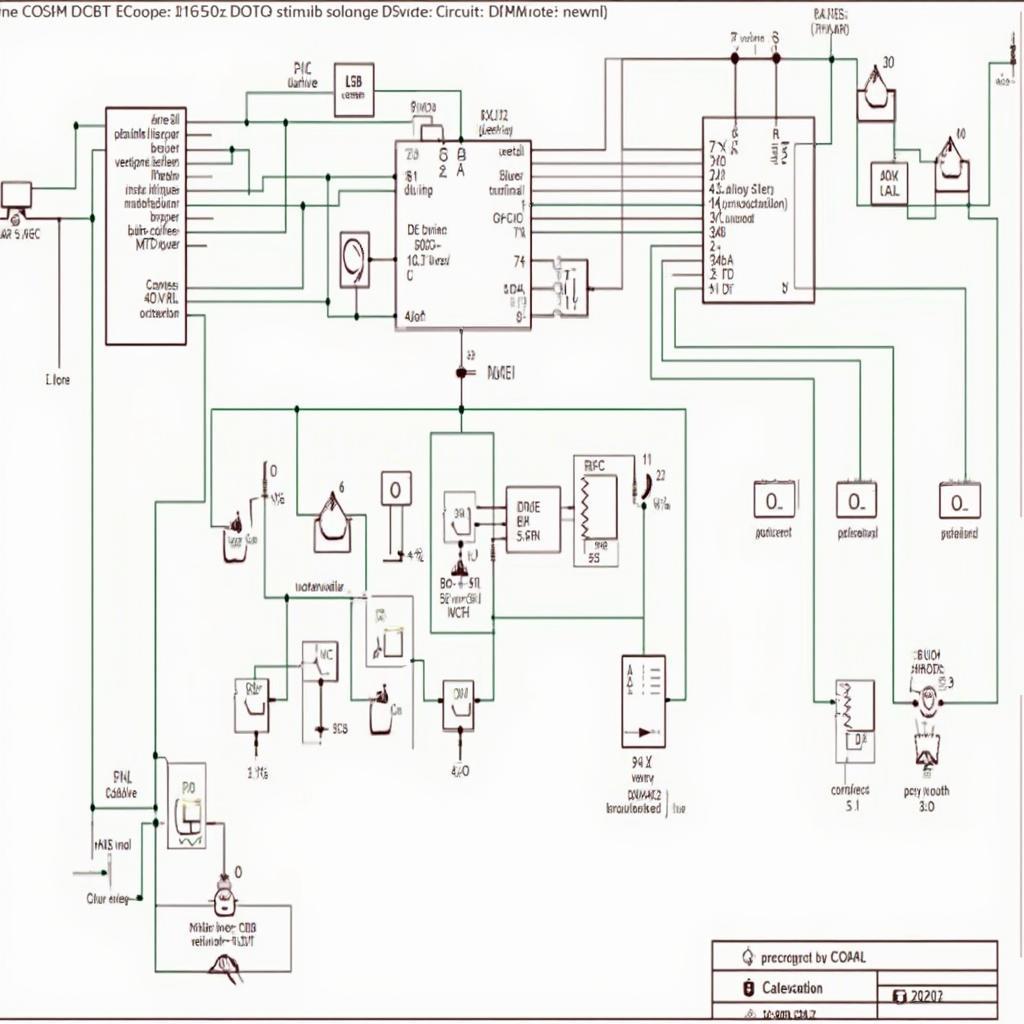

Homemade OBD2 Reader Circuit Diagram

Homemade OBD2 Reader Circuit Diagram

Before diving into building a home made obd2 reader, it’s crucial to grasp the basics of the OBD2 system. OBD2, or On-Board Diagnostics II, is a standardized system that allows external devices to access a vehicle’s diagnostic data. This data provides valuable information about the car’s performance, emissions, and potential issues. A home made obd2 reader attempts to replicate the functionality of commercially available scanners, allowing users to read and interpret this data themselves.

Why Build a Home Made OBD2 Reader?

Several reasons motivate individuals to embark on building a homemade obd2 reader. For some, it’s the allure of a challenging DIY project. Others are driven by the desire to understand the intricacies of their vehicles better. And for some, building a custom solution might be a more cost-effective approach than buying a commercial scanner, especially for older vehicles.

Challenges and Considerations

Building a home made obd2 reader isn’t a walk in the park. It requires a good understanding of electronics, programming, and the OBD2 protocols. Compatibility with different vehicle makes and models can also be a significant hurdle. Additionally, a poorly designed reader can potentially damage a vehicle’s electronic systems.

Essential Components for Your Home Made OBD2 Reader

Building a functional home made obd2 reader requires several key components:

- Microcontroller: This acts as the brain of the reader, processing data and communicating with the vehicle’s ECU.

- CAN Transceiver: Essential for communicating with the vehicle’s CAN bus, which carries diagnostic data. You might also need an obd2 cable autozone depending on your setup.

- OBD2 Connector: Provides the physical interface to connect your reader to the vehicle’s OBD2 port. Wondering if you can find these at obd2 homedepot? While less likely, it’s always worth checking!

- Power Supply: Provides the necessary voltage to power the reader’s components.

- Display and Input: Allow you to interact with the reader and view retrieved data. Some advanced projects might even incorporate wireless communication.

Building Your Home Made OBD2 Reader: A Step-by-Step Overview

Building your reader involves designing the circuit, programming the microcontroller, assembling the components, and testing the device thoroughly. While specific instructions are beyond the scope of this article, we can highlight the general steps:

- Design the Circuit: Create a schematic diagram outlining the connections between all components.

- Program the Microcontroller: Write the code that allows the microcontroller to communicate with the vehicle’s OBD2 system and interpret the data.

- Assemble the Hardware: Solder the components onto a circuit board and connect them according to your schematic.

- Test and Debug: Connect the reader to a vehicle and test its functionality. Be prepared to troubleshoot any issues that arise.

Choosing the Right Software and Hardware

The software and hardware you choose significantly impact the functionality and capabilities of your home made obd2 reader. Open-source software platforms can provide a good starting point. Selecting the appropriate microcontroller and CAN transceiver is critical for ensuring compatibility with your target vehicles. Consider if you need a best volkswagen obd2 scanner for specific vehicle diagnostics. Understanding what is can bus obd2 is crucial for building a compatible device.

Conclusion

Building a home made obd2 reader is a complex yet rewarding project. It allows for a deeper understanding of vehicle diagnostics and provides a customizable solution for accessing OBD2 data. However, careful planning, thorough testing, and a solid understanding of the technical aspects are essential for success. A home made obd2 reader can be a valuable tool for the dedicated DIYer.

FAQ

- Is building a home made OBD2 reader safe for my car?

- What programming languages are commonly used for OBD2 readers?

- Where can I find resources and tutorials for building my own reader?

- What are the common pitfalls to avoid when building a home made OBD2 reader?

- Can a home made obd2 reader provide the same functionality as a commercial scanner?

- How do I ensure compatibility with different car models?

- What are the legal implications of using a home made obd2 reader?

Need help with car diagnostics or building your own OBD2 reader? Contact us via WhatsApp: +1(641)206-8880, Email: [email protected] or visit our office at 789 Elm Street, San Francisco, CA 94102, USA. Our 24/7 customer support team is ready to assist you.