Your cart is currently empty!

Understanding John Deere OBD2: A Comprehensive Guide

John Deere Obd2 diagnostics have become essential for maintaining and troubleshooting modern agricultural machinery. This guide will delve into the specifics of John Deere OBD2 systems, exploring their functionalities, benefits, and how they empower owners and technicians to keep their equipment running smoothly.

Decoding John Deere OBD2 Systems

John Deere, a name synonymous with agricultural innovation, has integrated OBD2 (On-Board Diagnostics II) systems into its equipment to enhance diagnostics and maintenance. While based on the standardized OBD2 protocol, John Deere’s implementation has unique aspects tailored to the demands of agricultural machinery. These systems monitor various engine and emission-related parameters, providing valuable insights into the health and performance of the equipment.

What does John Deere OBD2 Tell You?

John Deere OBD2 systems provide a wealth of information, from engine speed and coolant temperature to fuel pressure and emissions data. This data helps pinpoint issues, enabling proactive maintenance and reducing downtime. The system stores Diagnostic Trouble Codes (DTCs), which act as clues, pointing towards specific problems.

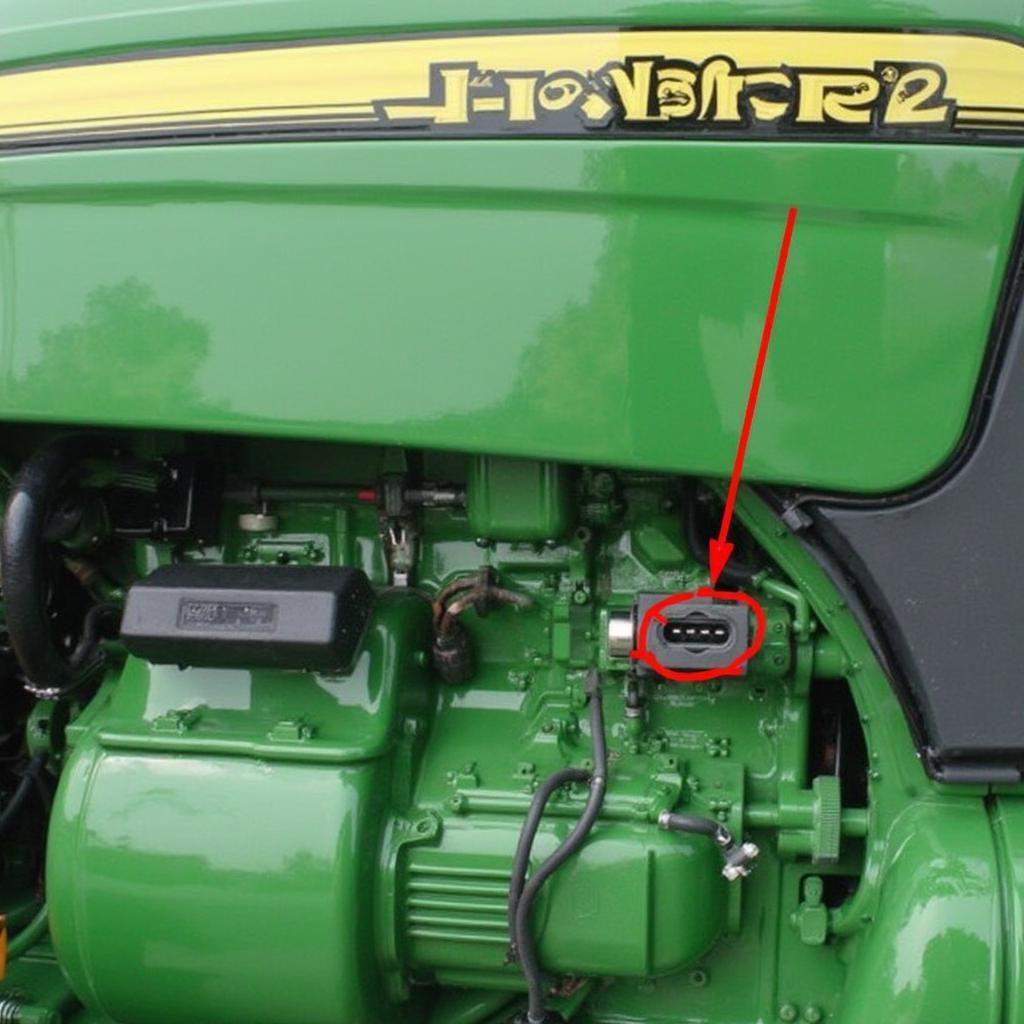

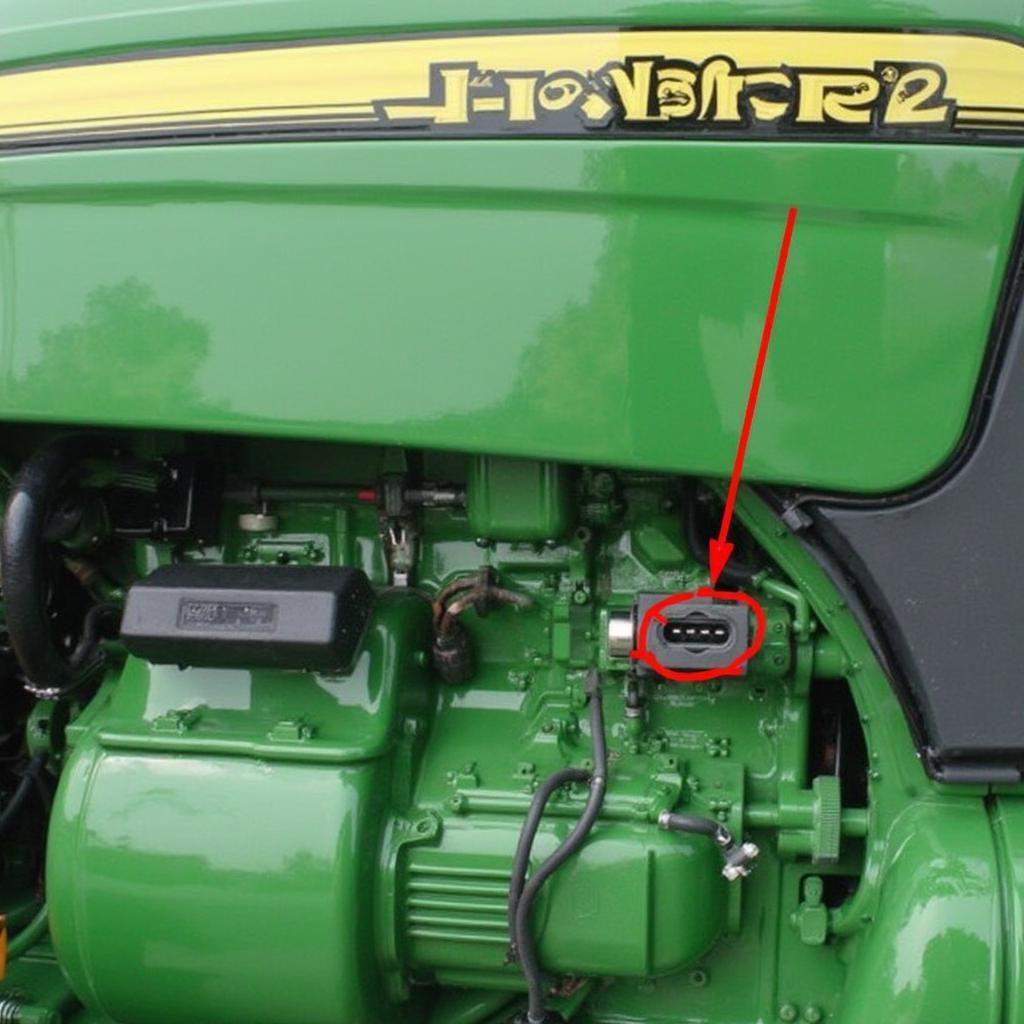

John Deere OBD2 Port Location

John Deere OBD2 Port Location

Benefits of Utilizing John Deere OBD2

Utilizing John Deere OBD2 diagnostics offers several significant advantages. Early problem detection minimizes costly repairs by addressing issues before they escalate. Improved maintenance scheduling optimizes equipment uptime, ensuring peak performance during critical operational periods. Furthermore, access to detailed performance data enables operators to fine-tune equipment settings for maximum efficiency and fuel economy.

John Deere OBD2 Scanners and Their Use

Choosing the right OBD2 scanner for your John Deere equipment is crucial. While generic OBD2 scanners can read basic engine codes, specialized John Deere diagnostic software and hardware unlock access to a wider range of data and functionalities. This allows for more in-depth analysis and precise troubleshooting.

Choosing the Right John Deere OBD2 Scanner

Consider factors like the specific models of John Deere equipment you own, the level of detail you require, and your budget when selecting a scanner. Some scanners offer advanced features like live data streaming, allowing you to monitor parameters in real-time.

Interpreting John Deere Diagnostic Trouble Codes (DTCs)

Understanding DTCs is key to effective troubleshooting. John Deere specific DTCs may differ from standard OBD2 codes. Consult your equipment’s service manual or use specialized John Deere diagnostic software to accurately interpret the codes and identify the root cause of problems.

“Understanding the nuances of John Deere’s OBD2 implementation is essential for effective diagnostics,” says Michael Johnson, a seasoned agricultural equipment technician with over 20 years of experience. “It allows us to pinpoint problems quickly and minimize downtime, which is critical for our clients.”

Beyond the Basics: Advanced John Deere Diagnostics

Advanced John Deere diagnostic tools provide deeper insights into equipment performance. These tools often include software that can analyze historical data, identify trends, and predict potential issues before they occur.

Predictive Maintenance with John Deere OBD2

Predictive maintenance leverages data analysis to anticipate potential failures. By monitoring various parameters and identifying patterns, technicians can schedule maintenance proactively, minimizing unexpected downtime and extending the lifespan of the equipment.

“Predictive maintenance is transforming how we manage our fleet,” adds Emily Carter, a farm manager in Iowa. “By anticipating problems, we can avoid costly breakdowns and optimize our operational efficiency.”

Conclusion

John Deere OBD2 systems are invaluable tools for maintaining and troubleshooting modern agricultural equipment. Understanding these systems, choosing the right diagnostic tools, and interpreting the data correctly empower owners and technicians to keep their equipment running efficiently and minimize downtime. Investing in John Deere OBD2 diagnostics is an investment in the long-term health and productivity of your agricultural operations.

FAQ

- What is John Deere OBD2? It’s the on-board diagnostic system used in John Deere equipment to monitor engine and emissions performance.

- Do I need a special scanner for John Deere OBD2? While generic scanners can read some codes, specialized John Deere scanners provide more comprehensive data.

- Where is the OBD2 port located on John Deere equipment? Consult your owner’s manual for the specific location on your model.

- What are John Deere DTCs? These are diagnostic trouble codes specific to John Deere equipment, indicating potential problems.

- How can I learn more about interpreting John Deere DTCs? Refer to your service manual or use specialized John Deere diagnostic software.

- What are the benefits of using John Deere OBD2? Benefits include early problem detection, improved maintenance scheduling, and enhanced equipment performance.

- What is predictive maintenance? It’s a strategy that uses data analysis to anticipate and prevent equipment failures.

Need support? Contact us via WhatsApp: +1(641)206-8880, Email: [email protected] or visit us at 789 Elm Street, San Francisco, CA 94102, USA. We offer 24/7 customer support.

Leave a Reply