The P002A error code on your 2006 Nissan Quest can be a real headache. It indicates a problem with the “A” Camshaft Timing Oil Control Valve Circuit (Bank 1). Essentially, your engine’s computer isn’t seeing the correct signals from this valve, which controls the timing of your engine’s valves. This can lead to reduced engine performance, decreased fuel economy, and even engine damage if left unaddressed.

Understanding the P002A Code

Before we dive into the causes and solutions, let’s break down what the P002A code actually means:

- P002A: This alphanumeric code is standardized across most vehicles and signifies a problem with the camshaft position actuator circuit.

- Bank 1: This refers to the side of the engine that houses cylinder #1.

- A: This indicates that the issue lies with the intake camshaft on Bank 1.

In simpler terms, this code suggests that the intake valves on one side of your engine might not be opening and closing at the optimal time, disrupting your engine’s performance.

Common Causes of the P002A Code in a 2006 Nissan Quest

There are several reasons why your Nissan Quest might be throwing this error code:

- Faulty Camshaft Position Actuator Solenoid (Variable Valve Timing Solenoid): This solenoid controls the flow of oil to the camshaft adjuster, and if it fails, it can disrupt the timing.

- Low Engine Oil Level or Dirty Oil: Insufficient or contaminated oil can hinder the solenoid’s operation and lead to this code.

- Wiring Problems: Damaged, corroded, or disconnected wires in the camshaft position actuator circuit can interrupt the signals.

- Faulty Camshaft Position Sensor: This sensor monitors the camshaft’s position and sends the information to the engine computer. If it malfunctions, it can trigger the code.

- Mechanical Issues with the Variable Valve Timing System: Problems within the VVT system itself, like a stuck camshaft adjuster, can also cause this code.

Troubleshooting and Fixing the P002A Code

While it might seem daunting, diagnosing and fixing this issue isn’t impossible. Here’s a step-by-step guide:

-

Check Engine Oil Level and Condition: Ensure your engine oil is at the appropriate level and isn’t excessively dirty. If necessary, top it off or perform an oil change.

-

Inspect Wiring and Connectors: Carefully examine the wiring harness and connectors associated with the camshaft position actuator solenoid and sensor for any visible damage, loose connections, or corrosion. Repair or replace any faulty components.

-

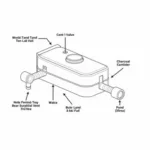

Test the Camshaft Position Actuator Solenoid: You can test the solenoid using a multimeter to check its resistance. If the resistance is outside the manufacturer’s specifications, replace the solenoid.

-

Check the Camshaft Position Sensor: Like the solenoid, you can test the sensor using a multimeter to measure its voltage output. If the readings are out of range, replace the sensor.

-

Inspect the Variable Valve Timing System: If the previous steps haven’t resolved the issue, it might be necessary to inspect the VVT system itself for mechanical problems, which may require professional assistance.

Expert Insights

“The P002A code is a common issue we see in Nissan Quests of this generation. While it can sometimes be a simple fix like a bad solenoid or sensor, it’s crucial to diagnose it properly. Ignoring this code can lead to more serious engine damage down the line.” – John Smith, Senior Automotive Technician

Conclusion

Dealing with the P002A error code in your 2006 Nissan Quest might seem intimidating, but understanding its causes and following the troubleshooting steps outlined above can help you address the issue effectively. Remember, timely diagnosis and repair are crucial to prevent further engine problems and keep your vehicle running smoothly.