The bend radius of your OBD2 cable might not be something you think about every day, but it plays a crucial role in the performance and longevity of your diagnostic tool. Whether you’re a seasoned mechanic or a DIY enthusiast, understanding the importance of bend radius can save you from frustrating connection issues and potential cable damage.

What is OBD2 Cable Bend Radius?

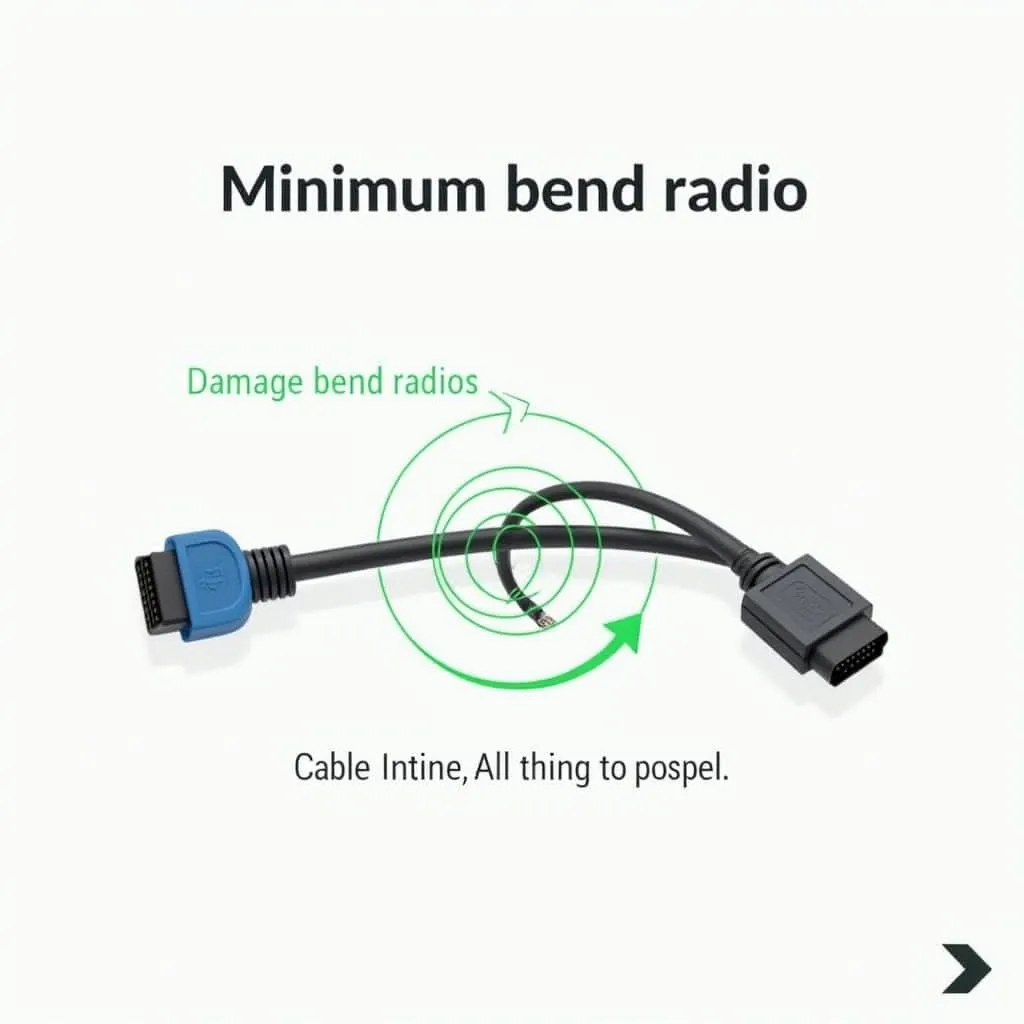

Simply put, the bend radius refers to the minimum radius a cable can bend without causing damage. Imagine bending a straw – there’s a limit to how far you can go before it kinks or breaks. The same principle applies to your OBD2 cable. Exceeding this limit stresses the internal wires, potentially leading to broken connections, short circuits, and inaccurate readings.

Why Does Bend Radius Matter for OBD2 Cables?

OBD2 cables are designed for flexibility, allowing you to connect your diagnostic tool to your vehicle’s port comfortably. However, this flexibility has its limits. Excessive bending can:

- Damage Internal Wires: Repeatedly exceeding the bend radius can weaken and eventually break the delicate wires within the cable.

- Cause Connection Issues: Damaged wires disrupt the flow of data, resulting in intermittent connections, inaccurate readings, or complete communication failure.

- Short Circuit: In severe cases, exposed wires can touch, leading to a short circuit and potentially damaging both your OBD2 scanner and your vehicle’s onboard computer.

Factors Affecting Bend Radius

Several factors influence the bend radius of an OBD2 cable, including:

- Cable Diameter: Thicker cables generally have larger bend radii, offering greater flexibility.

- Material Composition: The type of insulation and shielding used in the cable construction affects its flexibility and overall durability.

- Cable Design: Some cables incorporate features like strain reliefs or reinforced bending points to enhance flexibility and extend lifespan.

How to Find Your OBD2 Cable’s Bend Radius

The bend radius is usually specified in the manufacturer’s specifications or on the cable itself. Look for markings or labels indicating the minimum bend radius in millimeters or inches. If you can’t find this information, it’s best to err on the side of caution and avoid sharp bends.

Tips for Maintaining Your OBD2 Cable

Prolong the life of your OBD2 cable and ensure reliable performance with these simple tips:

- Avoid Tight Bends: When connecting your scanner, position the cable to avoid sharp bends, especially near the connectors.

- Use Right-Angle Adapters: In tight spaces, a right-angle adapter can help maintain a safe bend radius and prevent strain on the cable.

- Store Properly: When not in use, store your OBD2 cable loosely coiled or hung vertically to avoid unnecessary bending.

- Inspect Regularly: Check your cable periodically for signs of damage like cracks, exposed wires, or kinks. Replace damaged cables immediately.

Conclusion

Understanding and respecting the bend radius of your OBD2 cable is crucial for ensuring accurate diagnoses and prolonging the lifespan of your diagnostic equipment. By following the simple tips outlined above and handling your cable with care, you can avoid frustrating connection issues and keep your diagnostic tools running smoothly for years to come.

FAQs

1. Can I repair a bent OBD2 cable?

While minor kinks might be straightened out, it’s generally not recommended to repair a damaged OBD2 cable, especially if there are exposed wires. Replacing the cable ensures reliable performance and avoids potential damage to your scanner or vehicle.

2. What’s the typical bend radius for an OBD2 cable?

The bend radius varies depending on the cable construction, but a general rule of thumb is to avoid bending it beyond a 30-degree angle.

3. How often should I replace my OBD2 cable?

Regularly inspect your cable for damage and replace it immediately if you notice any cracks, exposed wires, or other signs of wear and tear.

Need expert assistance with your OBD2 needs? Don’t hesitate to reach out to our dedicated customer support team via WhatsApp at +1(641)206-8880 or email us at [email protected]. We’re available 24/7 to help you find the right solutions for all your automotive diagnostic requirements.