OBD2 CAN bus high voltage is a critical aspect of modern vehicle diagnostics. It’s essential to understand how this system works to effectively troubleshoot and maintain today’s increasingly complex cars and trucks. This article delves into the intricacies of high voltage CAN bus systems in OBD2, exploring their function, potential issues, and diagnostic procedures.

What is the OBD2 CAN Bus and How Does High Voltage Affect It?

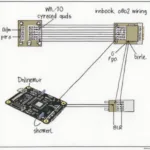

The Controller Area Network (CAN bus) is the communication backbone of your vehicle. It allows various modules, from the engine control unit (ECU) to the transmission control module (TCM), to exchange data seamlessly. With the rise of hybrid and electric vehicles, high voltage systems have been integrated, introducing new complexities to the CAN bus. These high voltage systems, often exceeding 60 volts, require specialized communication protocols and safety measures within the CAN bus architecture. This ensures that sensitive electronic components are protected while maintaining reliable data transmission. The high voltage CAN bus operates at a higher voltage level compared to the traditional 12V CAN bus, enabling efficient power transfer for electric motors and other high-voltage components. After the first paragraph, I thought a link to understanding OBD2 codes in general might be helpful. Let’s check out this resource: obd2 code p0402.

How Does High Voltage Impact OBD2 Diagnostics?

The integration of high voltage significantly impacts how OBD2 diagnostics are performed. Specialized equipment and procedures are often required to safely access and interpret data from high-voltage CAN bus systems. Ignoring these safety precautions can lead to damage to the diagnostic tool, the vehicle’s electronics, or even personal injury.

Common Issues Related to OBD2 CAN Bus High Voltage

Several issues can arise in high-voltage CAN bus systems. These include:

- Communication errors: High voltage fluctuations can disrupt communication between modules.

- Short circuits: Damage to wiring can lead to dangerous short circuits in high-voltage systems.

- Isolation faults: Compromised insulation can cause voltage leaks, affecting system performance.

“High voltage systems demand a higher level of caution and expertise during diagnostics,” advises John Miller, Senior Automotive Electrical Engineer at Future Auto Solutions.

Diagnosing OBD2 CAN Bus High Voltage Problems

Diagnosing high-voltage CAN bus issues requires specialized knowledge and tools. A technician needs to understand the specific communication protocols used by the vehicle and follow strict safety procedures. This involves using insulated tools and disconnecting the high-voltage battery before performing any work on the CAN bus system. Here’s a helpful tip: Always consult the vehicle’s service manual for specific instructions and safety precautions. It can save you a lot of headache down the road. You might be interested in learning more about OBD2 splitters: obd2 straight through splitter.

Safety Precautions When Working with High Voltage OBD2 Systems

- Disconnect the high-voltage battery: This is the most crucial step to prevent electrical shock.

- Use insulated tools: This protects against accidental contact with high-voltage components.

- Consult the vehicle’s service manual: Follow the manufacturer’s specific instructions and safety guidelines.

“Never underestimate the potential dangers of working with high voltage systems. Proper training and adherence to safety protocols are paramount,” warns Maria Sanchez, Lead Technician at Green Auto Repair.

Conclusion

OBD2 CAN bus high voltage systems are an integral part of modern vehicles. Understanding their functionality, potential problems, and diagnostic procedures is crucial for effective vehicle maintenance and repair. By prioritizing safety and utilizing the right tools and knowledge, technicians can effectively diagnose and resolve issues related to OBD2 CAN bus high voltage, ensuring the safe and efficient operation of today’s advanced vehicles. Don’t forget to check out this helpful link: oh monitor obd2.

FAQs

- What voltage is considered high voltage in an OBD2 system? Generally, anything above 60 volts is considered high voltage.

- Do I need special tools to diagnose high voltage OBD2 systems? Yes, specialized insulated tools and diagnostic equipment are necessary.

- What are the most common problems with high voltage OBD2 systems? Communication errors, short circuits, and insulation faults are common issues.

- Is it safe to work on high voltage OBD2 systems myself? Working with high voltage is dangerous and should be done by qualified technicians.

- Where can I find more information on high voltage OBD2 systems? Consult the vehicle’s service manual or contact a qualified technician.

- What should I do if I suspect a problem with my high voltage OBD2 system? Immediately take your vehicle to a qualified technician for diagnosis.

- How can I prevent problems with my high voltage OBD2 system? Regular maintenance and inspections by a qualified technician can help prevent issues.

Need more help? Check out our articles on konnwei obd2 pin and 98 cherokee obd2 code rich condition bank a.

Contact us via WhatsApp: +1(641)206-8880, Email: [email protected] or visit us at 789 Elm Street, San Francisco, CA 94102, USA. We have a 24/7 customer support team ready to assist you.