Understanding your 1997 Honda Accord’s obd2 distributor wiring on connectors is crucial for diagnosing and fixing engine problems. This article will provide a comprehensive guide to the wiring, connector locations, common issues, and troubleshooting tips.

Decoding the 1997 Honda Accord OBD2 Distributor Wiring

The distributor in your 1997 Honda Accord plays a vital role in the engine’s ignition system. It’s responsible for distributing high voltage to the spark plugs at the correct time, ensuring proper combustion. Understanding the obd2 distributor wiring on connectors is essential for anyone working on this system. The distributor connects to the Engine Control Module (ECM) via a wiring harness, and this connection allows the ECM to control the ignition timing.

Identifying the Connectors

Your 1997 Honda Accord’s distributor has several key connectors, each with a specific function. These connectors typically house wires for the ignition coil, crankshaft position sensor, and camshaft position sensor. Locating these connectors is the first step in understanding the wiring diagram.

Understanding the Wiring Diagram

A wiring diagram is like a roadmap for your car’s electrical system. It shows the connections between the distributor, the ECM, and other components. Using a wiring diagram specific to the 1997 Honda Accord will help you trace wires, identify connector pinouts, and diagnose any wiring issues.

Common Issues with OBD2 Distributor Wiring

Several problems can arise with the distributor wiring, including:

- Broken or frayed wires: This can lead to intermittent or complete loss of spark.

- Corroded connectors: Corrosion can disrupt the electrical connection, causing misfires or starting problems.

- Loose connections: A loose connection can cause similar issues to corroded connectors.

- Damaged sensors: A faulty crankshaft or camshaft position sensor can affect ignition timing.

Troubleshooting OBD2 Distributor Wiring Problems

If you suspect a problem with your distributor wiring, here are some troubleshooting steps:

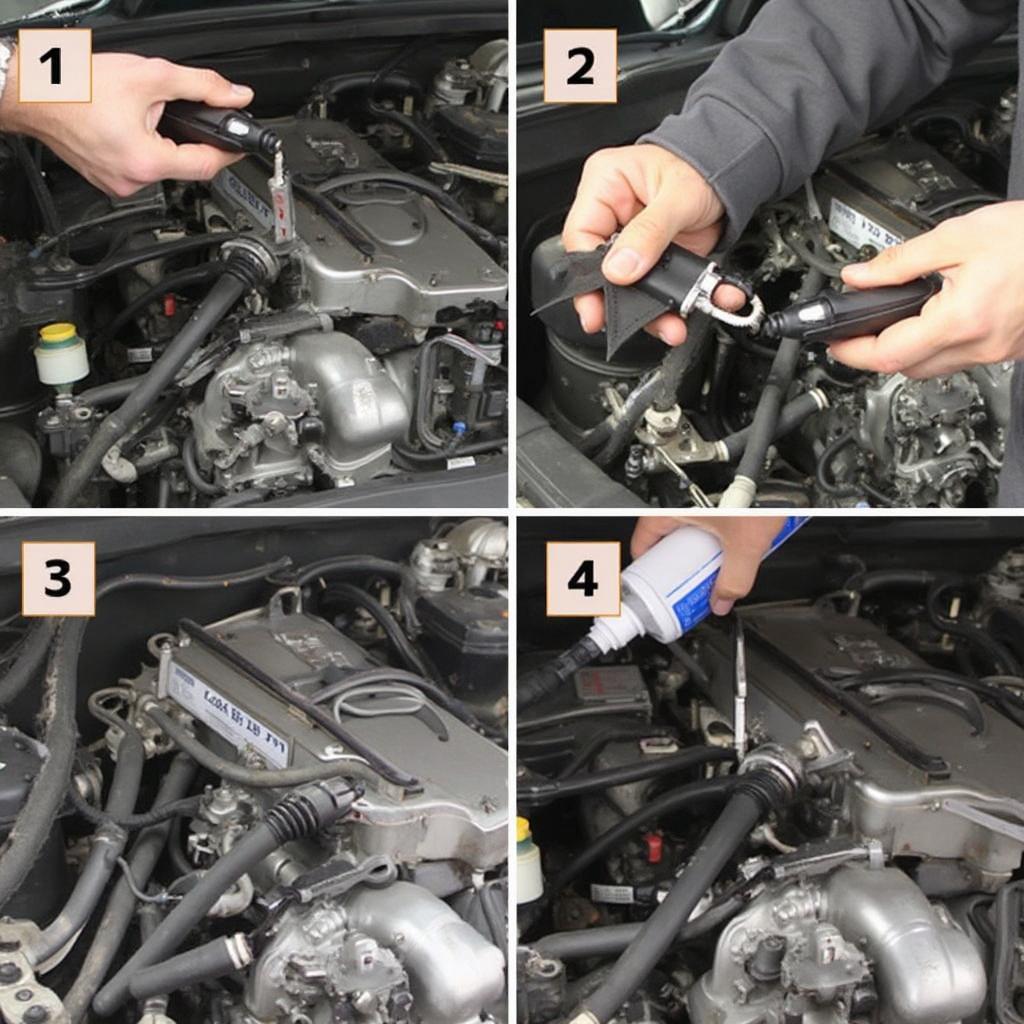

- Visually inspect the wiring and connectors: Look for any signs of damage, corrosion, or loose connections.

- Consult the wiring diagram: Use the diagram to identify the correct wire colors and pinouts.

- Use a multimeter: Test the continuity of the wires and the resistance of the sensors.

- Check for diagnostic trouble codes (DTCs): Use an OBD2 scanner to retrieve any stored codes, which can pinpoint the problem area.

Maintaining Your Distributor Wiring

Regular maintenance can help prevent wiring problems. This includes:

- Keeping the engine bay clean: Dirt and debris can contribute to corrosion.

- Inspecting the wiring and connectors periodically: Catch problems early before they become major issues.

- Using dielectric grease on connectors: This helps prevent corrosion.

“Regularly inspecting your distributor wiring is a simple yet effective way to prevent costly repairs down the road,” advises John Smith, ASE Certified Master Technician at Smith Automotive. “A little preventative maintenance can go a long way.”

1997 Honda Accord Distributor Maintenance

1997 Honda Accord Distributor Maintenance

Conclusion

Understanding your 1997 Honda Accord’s obd2 distributor wiring on connectors is fundamental for proper engine maintenance and repair. By familiarizing yourself with the wiring diagram, common issues, and troubleshooting steps, you can keep your Accord running smoothly. Regular inspection and maintenance are key to preventing costly repairs and ensuring optimal engine performance.

FAQ

- What are the common signs of a faulty distributor? Common signs include misfires, rough idling, difficulty starting, and decreased fuel efficiency.

- Where is the distributor located on a 1997 Honda Accord? The distributor is typically located on the side of the engine, near the firewall.

- Can I replace the distributor myself? While it’s possible, replacing a distributor requires some mechanical knowledge. If you’re unsure, consult a qualified mechanic.

- How often should I inspect my distributor wiring? It’s a good idea to inspect the wiring and connectors at least once a year or whenever you’re performing other engine maintenance.

- What is the role of the crankshaft position sensor? The crankshaft position sensor tells the ECM the position and speed of the crankshaft, which is crucial for ignition timing and fuel injection.

- What is the role of the camshaft position sensor? The camshaft position sensor tells the ECM the position of the camshaft, which is essential for determining which cylinder is firing.

- What tools do I need to troubleshoot distributor wiring problems? You’ll need a wiring diagram, a multimeter, and potentially an OBD2 scanner.

“Addressing distributor wiring issues promptly is essential,” adds Maria Garcia, Lead Electrical Systems Engineer at AutoTech Solutions. “Ignoring these problems can lead to more significant engine damage and costly repairs.”

Need Help? Contact us via WhatsApp: +1(641)206-8880, Email: [email protected] or visit us at 789 Elm Street, San Francisco, CA 94102, USA. We have a 24/7 customer support team.