A blown obd2 fuse in your Cummins engine can be a frustrating experience, especially when you’re trying to diagnose a check engine light. Understanding the causes, symptoms, and solutions for this issue is crucial for getting your truck back on the road. This article will guide you through everything you need to know about an obd2 fuse blown cummins, from troubleshooting to preventative measures.

If you’re experiencing issues with your Cummins OBD2 port, a blown fuse might be the culprit. Common signs include a non-responsive scanner or an inability to establish communication with the vehicle’s computer.

Several factors can lead to a blown obd2 fuse in a Cummins. These include short circuits in the OBD2 port wiring, faulty diagnostic equipment, or even a surge in the electrical system. Identifying the root cause is essential for preventing future occurrences.

Understanding the OBD2 System in Cummins Engines

The OBD2 (On-Board Diagnostics, second generation) system is a standardized system that allows external diagnostic tools to communicate with a vehicle’s computer, retrieving valuable data about engine performance and emissions. It’s a vital tool for troubleshooting and maintaining your Cummins engine. A blown fuse interrupts this communication, hindering diagnostic efforts. After you fix the obd2 fuse blown cummins, you will be able to use your scanner again. You can learn more about common OBD2 port issues by checking out this article: 6.7 cummins obd2 port problems.

Identifying a Blown OBD2 Fuse in Cummins

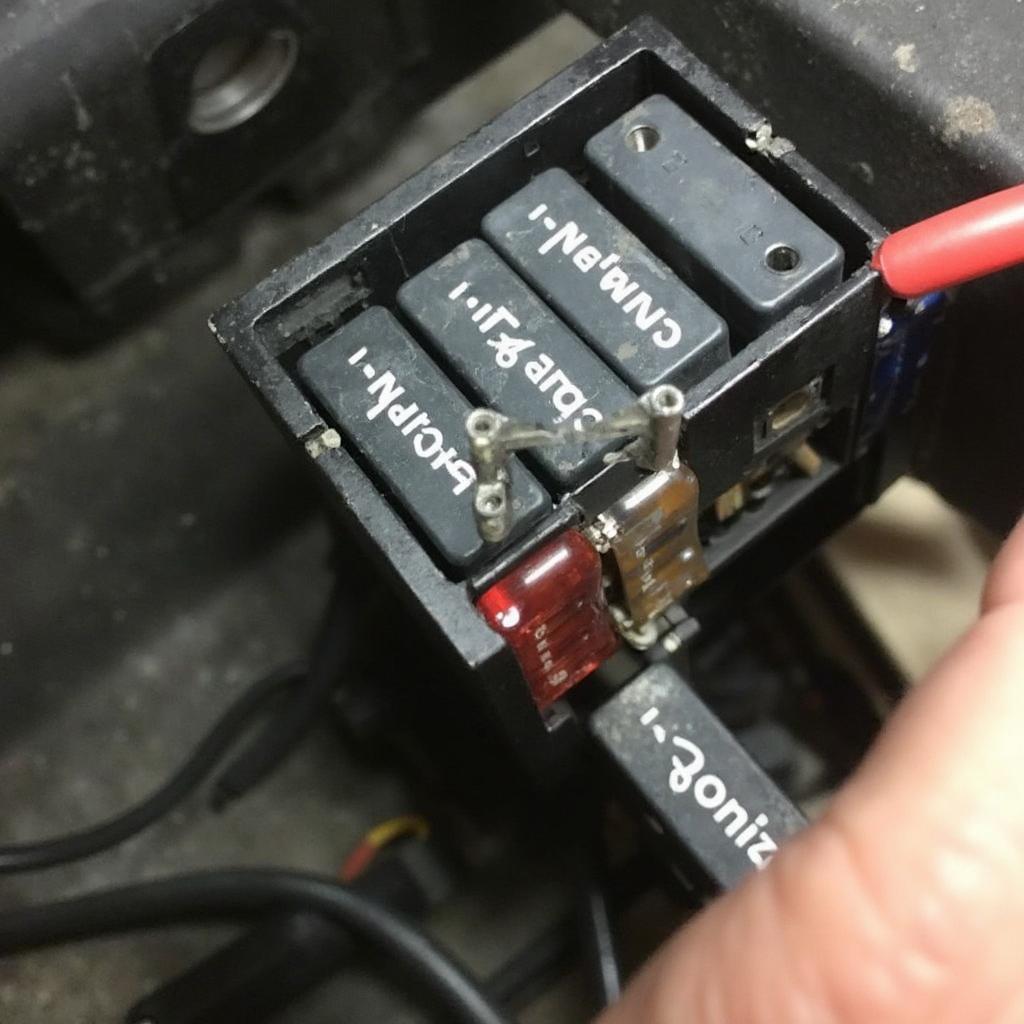

Locating the OBD2 fuse in your Cummins can sometimes be challenging. Refer to your owner’s manual for the precise location, which typically resides within the fuse box under the hood or dash. Visually inspect the fuse for a broken filament or use a multimeter to test its continuity.

Troubleshooting an OBD2 Fuse Blown Cummins

Before replacing the fuse, it’s vital to determine the underlying cause. A simple replacement might only be a temporary fix. Inspect the OBD2 port for any signs of damage, debris, or corrosion. Check the wiring for any shorts or loose connections. Consider the possibility of a faulty diagnostic tool. If you’re dealing with a 1996 Dodge Cummins, finding the right fuse can be particularly tricky. This guide can help: obd2 fuses 1996 dodge cummins.

Replacing the OBD2 Fuse in Your Cummins

Once you’ve identified the blown fuse and hopefully addressed the root cause, replace it with a fuse of the correct amperage. Using an incorrect fuse can lead to further electrical issues. Always consult your owner’s manual for the specified amperage. What if you can’t connect to your OBD2 port? This article offers solutions: can’t connect to obd2.

Preventing Future OBD2 Fuse Issues

Preventing blown fuses is always better than dealing with the aftermath. Ensure your diagnostic equipment is in good working order. Avoid using cheap or counterfeit OBD2 scanners, which can cause electrical issues. Regularly inspect your OBD2 port and wiring for damage. Protecting your OBD2 port from the elements can also help prolong its lifespan. Smog checks can sometimes reveal OBD2 connection issues. Here’s a resource if you encounter this problem: smog can’t connect to obd2 dodge cummins.

Expert Insights on OBD2 Fuse Issues

“A blown OBD2 fuse is often a symptom of a larger problem,” says automotive expert, John Smith, ASE Certified Master Technician. “Don’t just replace the fuse and hope for the best. Take the time to diagnose the underlying cause to avoid recurring issues.”

Another expert, Maria Garcia, an Electrical Systems Engineer, adds, “Using the correct amperage fuse is critical. Using a higher amperage fuse might seem like a quick fix, but it can damage sensitive electronics and even create a fire hazard.”

In conclusion, addressing an obd2 fuse blown cummins requires more than just replacing the fuse. Understanding the potential causes and implementing preventative measures will save you time and frustration down the road. For information on the location of your OBD2 port fuse, check out this helpful guide: obd2 port fuse location.

FAQ

- What is the most common cause of a blown OBD2 fuse? Short circuits are the most common cause.

- Can a faulty OBD2 scanner blow a fuse? Yes, a faulty scanner can cause a short circuit and blow the fuse.

- Where is the OBD2 fuse located in a Cummins? Consult your owner’s manual for the exact location.

- What amperage fuse should I use for the OBD2 port? Refer to your owner’s manual for the correct amperage.

- Can I drive with a blown OBD2 fuse? Yes, but you won’t be able to use diagnostic tools.

- What should I do if the fuse blows again after replacement? Have a qualified mechanic inspect the electrical system.

- How can I prevent my OBD2 fuse from blowing? Ensure proper use of diagnostic tools and regular maintenance.

Need further assistance? Contact us via WhatsApp: +1(641)206-8880, Email: [email protected] or visit us at 789 Elm Street, San Francisco, CA 94102, USA. Our 24/7 customer support team is ready to help.