OBD2 PIC projects offer a fascinating gateway into the inner workings of your vehicle. By combining the power of an OBD2 interface with the versatility of a PIC microcontroller, you can unlock a wealth of diagnostic data and even implement custom control functionalities. This article delves into the exciting world of OBD2 PIC projects, providing a comprehensive guide for enthusiasts and professionals alike.

Connecting an OBD2 interface to a PIC microcontroller opens a world of possibilities for vehicle diagnostics and control. Whether you’re a seasoned automotive enthusiast or just starting out, this guide will provide valuable insights into harnessing the power of OBD2 PIC projects. From simple data logging to advanced control systems, the potential is vast. Here at OBDFree, we’re dedicated to providing comprehensive and reliable information on all things OBD2. After this first section, you can check out our guide on STM32 CAN OBD2 for more information on microcontroller applications.

Understanding the Basics of OBD2 and PIC Microcontrollers

Before diving into OBD2 PIC projects, it’s essential to understand the fundamental components involved: the OBD2 interface and the PIC microcontroller. OBD2, short for On-Board Diagnostics II, is a standardized system that allows external devices to access vehicle diagnostic data. This data includes everything from engine RPM and speed to fault codes and sensor readings. PIC microcontrollers, on the other hand, are small, programmable computers that can be used to interface with and control various electronic systems.

What is OBD2?

OBD2 is a standardized system for accessing vehicle diagnostic data. It provides a common interface for retrieving information about the engine, transmission, and other critical systems. This data can be used for troubleshooting, performance monitoring, and even custom control applications.

What is a PIC Microcontroller?

PIC microcontrollers are small, programmable computers that can be used for a wide range of embedded applications. They are inexpensive, versatile, and relatively easy to program, making them ideal for hobbyists and professionals alike.

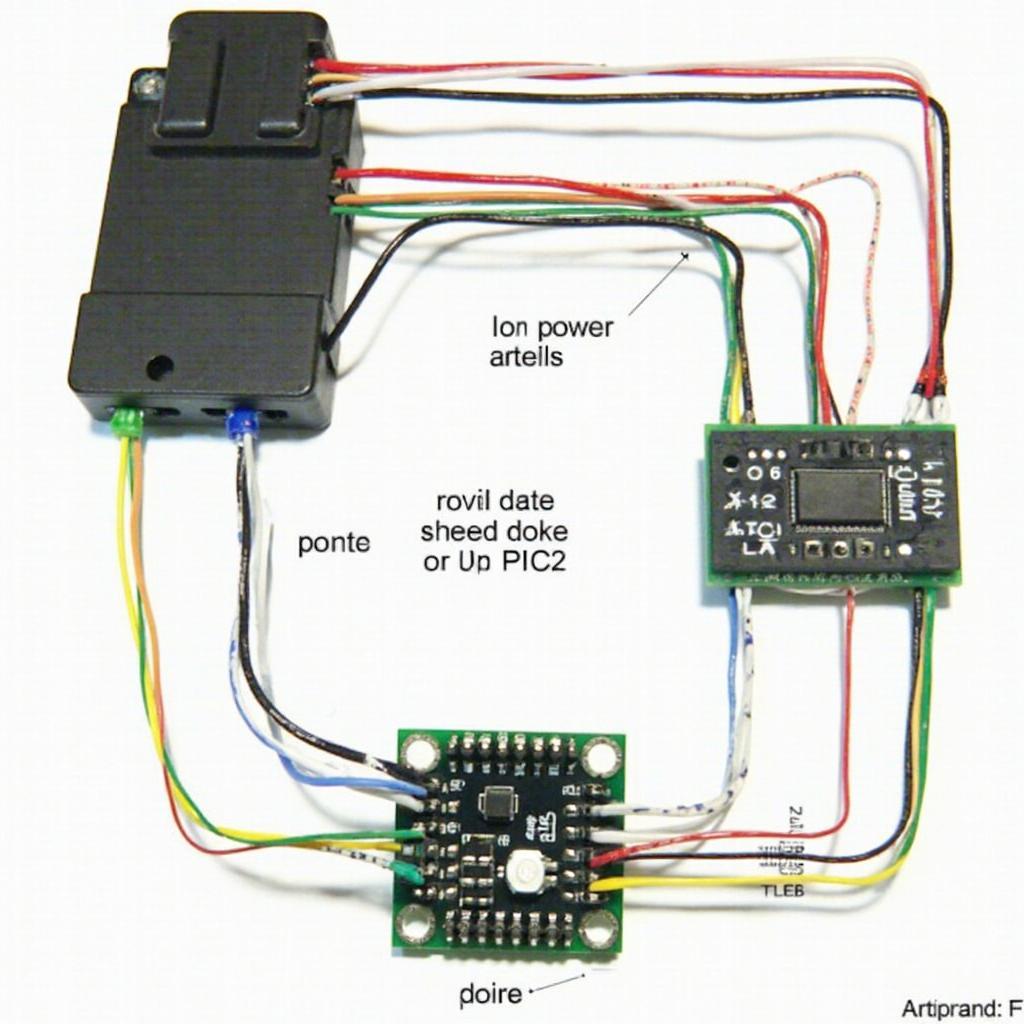

Connecting OBD2 Interface to PIC Microcontroller

Connecting OBD2 Interface to PIC Microcontroller

Getting Started with OBD2 PIC Projects

Embarking on your first OBD2 PIC project can seem daunting, but with the right guidance, it can be a rewarding experience. The first step is selecting the appropriate hardware and software. You’ll need an OBD2 interface, a PIC microcontroller, a programming tool, and a suitable development environment.

Choosing the Right Hardware

Selecting the correct hardware is crucial for success. Choose an OBD2 interface that is compatible with your vehicle and the PIC microcontroller you plan to use. Consider factors such as voltage levels, communication protocols, and physical connectors. The del Sol OBD2 VTEC tuck harness is a popular option for Honda enthusiasts.

Setting up the Software

Once you have the hardware in place, you need to set up the software environment. This includes installing the necessary drivers, programming tools, and a suitable development environment, like MPLAB X IDE, for writing and compiling your code.

Building Your First OBD2 PIC Project: Reading Engine RPM

A classic introductory project is reading the engine RPM from your vehicle’s OBD2 port. This simple project demonstrates the fundamental principles of OBD2 communication and data retrieval.

Connecting to the OBD2 Port

Connect the OBD2 interface to your vehicle’s OBD2 port, usually located under the dashboard on the driver’s side. Ensure a secure connection to prevent data loss or errors during communication. You might need an OBD2 replacement connector if the original one is damaged.

Sending and Receiving Data

Using the appropriate OBD2 commands (PIDs), request the engine RPM data from the vehicle’s ECU. The PIC microcontroller will receive this data, process it, and display it on an output device, such as an LCD screen. Check out our resource on OBD2 to USB-C for modern connectivity options.

Advanced OBD2 PIC Projects

Once you’ve mastered the basics, the possibilities are endless. You can expand your projects to include data logging, custom dashboards, and even control functionalities.

Data Logging

Log various vehicle parameters like speed, engine temperature, and fuel consumption over time. This data can be valuable for performance analysis and troubleshooting.

Custom Dashboards

Create your own custom dashboards displaying the information you need in a format you prefer.

Control Functionalities

With more advanced programming, you can even control certain aspects of your vehicle’s operation using OBD2 commands and the PIC microcontroller. For instance, an OBD2 to OBD1 injector harness can be used for specific engine modifications.

Conclusion

OBD2 PIC projects offer an exciting way to explore the world of automotive electronics. From basic diagnostics to advanced control systems, the versatility of these projects is limited only by your imagination. By understanding the fundamentals and applying the techniques discussed, you can unlock the secrets of your car and create truly innovative applications. So dive in, explore, and master the art of OBD2 PIC projects. Remember, OBD2 PIC projects empower you to understand your car better.

FAQs

-

What is the cost of starting an OBD2 PIC project? The cost can vary depending on the components chosen. However, basic projects can be started with a relatively small investment.

-

What programming languages are used for OBD2 PIC projects? Commonly used languages include C and assembly language.

-

Are there pre-built OBD2 PIC project kits available? Yes, several kits are available to simplify the initial setup and learning process.

-

Is it safe to experiment with OBD2 PIC projects in my car? With careful planning and proper precautions, OBD2 PIC projects can be safely implemented.

-

Where can I find more resources and tutorials on OBD2 PIC projects? Online forums, communities, and educational websites offer a wealth of information.

If you need further assistance, don’t hesitate to contact us via WhatsApp: +1(641)206-8880, Email: [email protected] or visit us at 789 Elm Street, San Francisco, CA 94102, USA. Our 24/7 customer support team is ready to help. You can also explore other relevant articles on our website, such as articles on specific OBD2 connectors or other microcontroller applications.