The automotive world underwent a significant transformation with the introduction of On-Board Diagnostics (OBD) systems. These systems, designed to monitor and report vehicle emissions and performance, have evolved from their rudimentary OBD1 beginnings to the sophisticated OBD2 standard we know today. But what exactly are the differences between OBD2 vs OBD1?

This comprehensive guide delves into the nuances of each system, providing clarity on their functionalities, benefits, and how they impact your vehicle ownership experience.

Understanding the Basics: What is OBD?

Before dissecting the disparities between OBD2 vs OBD1, it’s crucial to grasp the fundamental concept of OBD. Imagine your car having a built-in mechanic, constantly analyzing its vital signs. That’s essentially what OBD does.

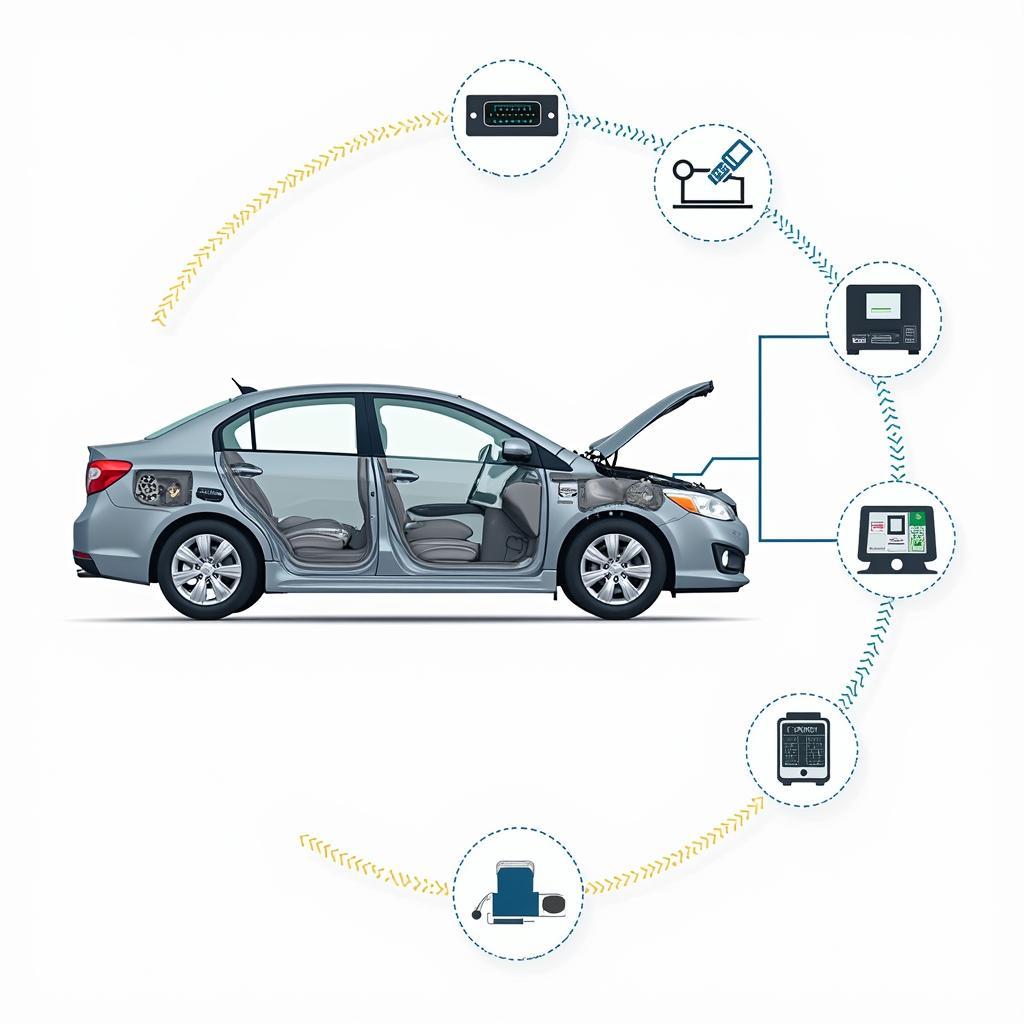

This system comprises a network of sensors strategically placed throughout your vehicle, meticulously collecting data on various components and processes. This data is then relayed to a central computer, the Engine Control Unit (ECU), which acts as the brain of your car’s operations.

OBD1: The Pioneer

Introduced in the late 1980s, OBD1 marked the initial foray into standardized vehicle diagnostics. Primarily focused on monitoring emissions-related components, OBD1 systems were relatively simplistic compared to their successors.

Here’s a glimpse into the key characteristics of OBD1:

-

Limited Scope: OBD1 primarily monitored components directly related to emissions, such as the catalytic converter, oxygen sensor, and exhaust gas recirculation (EGR) valve.

-

Manufacturer Specific: One of the significant drawbacks of OBD1 was the lack of standardization across car manufacturers. Each automaker had its proprietary connector type, protocols, and even trouble code interpretations. This lack of uniformity made diagnostics challenging for mechanics unfamiliar with a particular vehicle model.

-

Rudimentary Diagnostics: OBD1 systems relied on basic “blink codes” to signal issues. Mechanics had to decipher these flashing lights on the dashboard, often requiring consultation with manufacturer-specific manuals.

OBD2: The Evolution

The need for a more standardized and comprehensive diagnostic system led to the development of OBD2, implemented in 1996 for all new vehicles sold in the United States. OBD2 expanded upon its predecessor in several key areas:

-

Standardized Connectors and Protocols: A universal 16-pin connector became mandatory, eliminating the confusion of multiple connector types. Furthermore, standardized communication protocols allowed for seamless data retrieval across different vehicle makes and models.

-

Expanded Monitoring: OBD2 broadened its monitoring scope beyond emissions, encompassing a wider array of vehicle systems, including the engine, transmission, airbags, and anti-lock brakes. This comprehensive approach provided a more detailed insight into a vehicle’s overall health.

-

Detailed Trouble Codes: OBD2 introduced a standardized system of Diagnostic Trouble Codes (DTCs), each with a specific definition. This standardization streamlined diagnostics, allowing mechanics to quickly pinpoint the root cause of issues.

-

Real-Time Data: OBD2 scanners could access and display real-time data from various sensors, providing valuable information about engine performance, fuel efficiency, and other crucial parameters.

OBD2 vs OBD1: The Key Differences

While the evolution from OBD1 to OBD2 brought about significant improvements, understanding the core differences between these systems is crucial:

| Feature | OBD1 | OBD2 |

|---|---|---|

| Year of Introduction | Late 1980s | 1996 |

| Diagnostic Connector | Manufacturer-specific | Standardized 16-pin |

| Communication Protocols | Proprietary | Standardized (e.g., CAN bus) |

| Monitoring Scope | Primarily emissions-related | Expanded to include engine, transmission, airbags, ABS, and more |

| Trouble Codes | Manufacturer-specific “blink codes” | Standardized Diagnostic Trouble Codes (DTCs) |

| Data Access | Limited | Real-time data from various sensors |

Choosing the Right OBD Scanner

The type of OBD system your vehicle uses dictates the kind of scanner you’ll need.

-

For OBD1 Vehicles: You’ll require a scanner specifically designed for your vehicle’s make and model. These scanners are often less common and may require some research to find.

-

For OBD2 Vehicles: A wide array of OBD2 scanners is available, ranging from basic code readers to advanced professional-grade tools.

When choosing an OBD2 scanner, consider your needs and budget. Basic code readers are affordable and sufficient for DIY enthusiasts looking to understand and clear simple trouble codes. On the other hand, professional mechanics and advanced users might opt for high-end scanners offering live data streaming, graphing capabilities, and advanced diagnostic functions.

Conclusion

Understanding the evolution and differences between OBD2 vs OBD1 is essential for any car owner or enthusiast. While OBD1 laid the groundwork for vehicle diagnostics, OBD2 revolutionized the field with its standardized approach, expanded capabilities, and user-friendliness.

Whether you’re a DIYer looking to troubleshoot a check engine light or a professional mechanic seeking in-depth vehicle analysis, OBD2 scanners have become indispensable tools in the automotive world. Choosing the right scanner empowers you to take control of your vehicle’s health and make informed decisions about its maintenance.