Pre-OBD2 evaporative emission control systems, often shortened to “pre-OBD2 evaporative system,” represent a crucial step in automotive history. These systems, designed to prevent fuel vapors from escaping into the atmosphere, were implemented before the standardized OBD2 diagnostics we know today. This means troubleshooting them requires a different approach than using a modern obd2 scanner up to 2018. Understanding how these pre-OBD2 systems function, their common issues, and diagnostic techniques is essential for anyone working on older vehicles.

What is a Pre-OBD2 Evaporative System?

A pre-OBD2 evaporative system’s primary function is to capture and store fuel vapors from the fuel tank and fuel lines. These vapors, which are hydrocarbons, contribute to smog and are harmful to the environment. The system prevents these vapors from escaping by storing them in a charcoal canister and then purging them into the engine for combustion. While the core concept remained the same, the specific components and control strategies varied significantly between manufacturers and even model years.

Key Components of a Pre-OBD2 Evaporative System

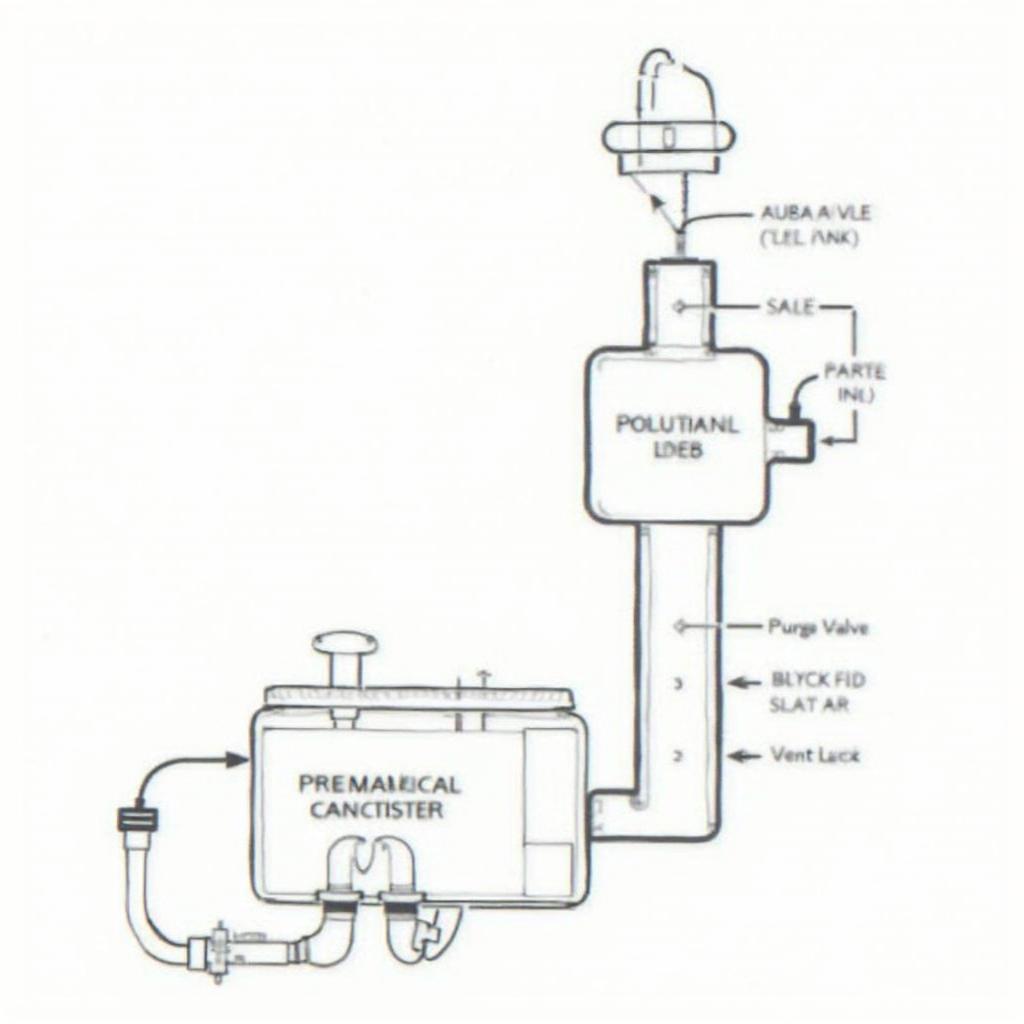

Several key components work together in a pre-OBD2 evaporative system:

- Fuel Tank: The starting point, where fuel vapors originate.

- Charcoal Canister: A container filled with activated charcoal that absorbs and stores the fuel vapors.

- Purge Valve: Controls the flow of vapors from the charcoal canister to the intake manifold.

- Vent Valve: Allows air to enter the canister to aid in purging.

- Vacuum Lines and Hoses: Connect the various components and allow for the movement of vapors and air.

Common Problems in Pre-OBD2 Evaporative Systems

Due to the simpler design and lack of sophisticated diagnostics, pre-OBD2 evaporative systems can experience several common problems:

- Leaking Hoses and Lines: Cracks or deterioration in the hoses and lines can lead to vapor leaks.

- Faulty Purge Valve: A malfunctioning purge valve can disrupt the flow of vapors, causing performance issues or fuel smell.

- Clogged Charcoal Canister: Over time, the charcoal canister can become saturated and clogged, preventing it from effectively absorbing vapors.

- Damaged Vent Valve: A stuck or damaged vent valve can restrict airflow, impacting the system’s ability to purge.

Diagnosing Pre-OBD2 Evaporative Systems

Diagnosing these systems requires a more hands-on approach than OBD2 systems. Here’s a simplified process:

- Visual Inspection: Carefully examine all hoses, lines, and connections for signs of damage or leaks.

- Smoke Test: Introduce smoke into the system to pinpoint leaks.

- Purge Valve Test: Check the operation of the purge valve using a vacuum pump or by manually activating it.

- Charcoal Canister Inspection: Inspect the canister for signs of damage or clogging. Replacement is often the best course of action for a suspected faulty canister.

Why Understanding Pre-OBD2 Systems Matters

While modern vehicles utilize OBD2, understanding pre-OBD2 systems is vital for anyone working with older cars. These systems can still cause drivability issues and contribute to environmental pollution. Proper diagnosis and repair are essential for maintaining these vehicles and keeping them running smoothly. This knowledge can be particularly useful when dealing with vehicles that predate standardized obd2 ford ba systems.

“Understanding the nuances of pre-OBD2 evaporative systems is crucial for classic car enthusiasts and mechanics alike,” says Arnold Swanson, a veteran automotive technician with over 30 years of experience. “These systems require a different diagnostic mindset than their modern counterparts.”

Conclusion

Pre-OBD2 evaporative systems played a significant role in reducing emissions before the widespread adoption of OBD2. While simpler in design, they require a different approach to diagnosis and repair. Understanding their components, common issues, and diagnostic techniques is essential for maintaining older vehicles and minimizing their environmental impact. If you are struggling with a pre-obd2 evaporative system and your obd2 history says pass, you likely need a different diagnostic approach.

FAQ

- What is the main purpose of an evaporative emission control system? To prevent fuel vapors from escaping into the atmosphere.

- How does a charcoal canister work? It absorbs and stores fuel vapors using activated charcoal.

- What is a purge valve? It controls the flow of vapors from the canister to the engine.

- How do I test a pre-OBD2 evaporative system? Visual inspection, smoke tests, and component testing are common methods.

- Why is it important to maintain a functioning evaporative system? To reduce emissions and ensure proper vehicle operation.

- What are some signs of a faulty evaporative system? Fuel smell, poor performance, and failed emissions tests.

- Can I use an OBD2 scanner on a pre-OBD2 evaporative system? No, these systems require different diagnostic methods.

Common Scenarios and Questions:

- Scenario: Strong fuel smell inside the car. Question: Could this be a leak in the evaporative system?

- Scenario: Engine runs rough after refueling. Question: Could a stuck purge valve be the culprit?

- Scenario: Failed emissions test. Question: How do I check the evaporative system for leaks?

Further Exploration

For more information on OBD2 systems and other car diagnostic topics, explore other articles on our website.

Contact Us

Need assistance with your car diagnostics? Contact us via WhatsApp: +1(641)206-8880, Email: [email protected] or visit us at 789 Elm Street, San Francisco, CA 94102, USA. Our customer service team is available 24/7.