Connecting your STM32 microcontroller to your car’s OBD2 port opens a world of possibilities for DIY projects, diagnostics, and data logging. This article explores the world of STM32 CAN OBD2, providing you with a comprehensive understanding of the hardware, software, and protocols involved.

Understanding the Basics of STM32 CAN OBD2

An STM32 microcontroller is a versatile platform perfect for interfacing with your vehicle’s OBD2 system. The Controller Area Network (CAN) bus is the communication backbone of modern vehicles, and the OBD2 port provides a readily accessible connection point. By leveraging the STM32’s CAN capabilities, you can tap into a wealth of vehicle data. Utilizing the STM32’s processing power allows for real-time data analysis and implementation of custom control strategies. With the right knowledge, an STM32 can become your personalized car diagnostic tool.

Setting Up Your STM32 for CAN Communication

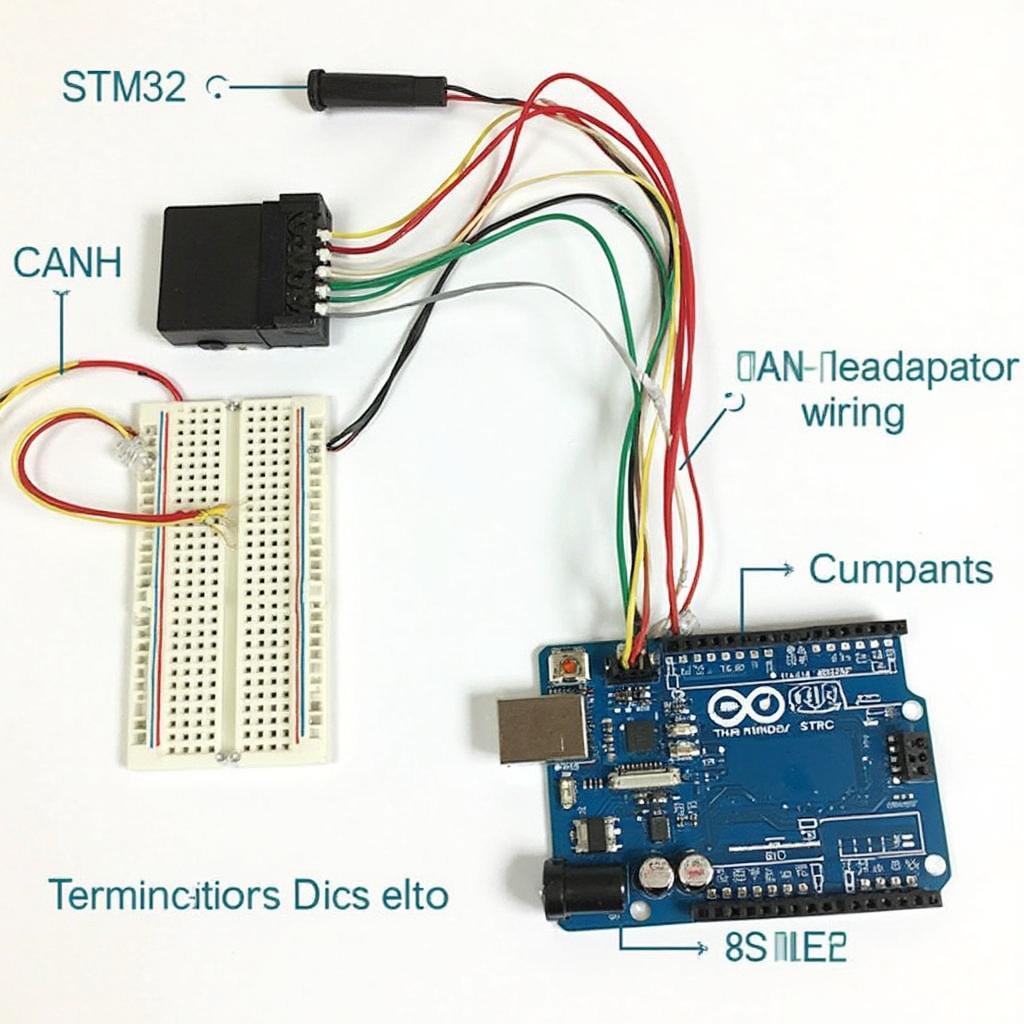

Before diving into code, you need to ensure your hardware is properly configured. This involves connecting the STM32’s CAN transceiver to the OBD2 port’s CAN lines (typically pins 6 and 14). A CAN transceiver acts as the interface between the microcontroller and the physical CAN bus. Also, consider the required voltage levels and termination resistors for proper signal integrity.

Selecting the correct STM32 microcontroller is crucial, considering factors like CAN peripheral availability and processing power. The STM32CubeMX configuration tool simplifies the initialization process, allowing you to configure the CAN peripheral with the desired baud rate and other parameters. This tool is a lifesaver, especially for those new to the STM32 ecosystem.

Decoding OBD2 Data with Your STM32

Once your hardware is set up, you can start writing code to interact with the OBD2 system. The OBD2 protocol utilizes standardized message formats (PIDs) to request specific data from the vehicle’s Electronic Control Unit (ECU). Sending these requests via the CAN bus using your STM32, you can retrieve information like engine speed, coolant temperature, and fuel level. Processing and displaying this data on an LCD or sending it to a computer opens up numerous possibilities for custom applications.

Understanding the structure of OBD2 PIDs is fundamental for effective communication. These PIDs are essentially codes that correspond to specific data points within the vehicle’s system. For example, requesting PID 0x0C returns engine RPM. By sending the correct PID request and parsing the response from the ECU, you can extract the desired data.

Building Your Own OBD2 Projects with STM32

The possibilities are endless when it comes to utilizing STM32 CAN OBD2 for your projects. You can build a custom diagnostics tool tailored to your specific needs, a data logger to track vehicle performance, or even a sophisticated monitoring system. Implementing these projects requires a solid understanding of the OBD2 protocol and the STM32’s CAN capabilities.

Imagine building a custom display that shows real-time fuel economy based on OBD2 data or creating a warning system triggered by specific diagnostic trouble codes (DTCs). These are just a few examples of what you can achieve with some creativity and programming skills. The STM32 provides the perfect platform to bring these ideas to life.

Conclusion

STM32 CAN OBD2 offers a powerful and flexible solution for accessing and utilizing vehicle data. By understanding the basics of CAN communication, OBD2 protocols, and STM32 programming, you can unlock a world of potential for DIY projects and customized automotive solutions. From simple diagnostics to sophisticated data logging, the STM32 empowers you to take control of your vehicle’s data. So, start exploring the world of STM32 CAN OBD2 and unleash your creativity!

FAQ

-

What is the role of a CAN transceiver in STM32 OBD2 communication?

- A CAN transceiver adapts the STM32’s logic levels to the CAN bus voltage levels, enabling proper communication.

-

Which STM32 microcontrollers are suitable for OBD2 projects?

- Many STM32 microcontrollers have CAN peripherals. Choose one with sufficient processing power and memory for your project.

-

How can I decode OBD2 data received by the STM32?

- OBD2 data is formatted using PIDs. Parse the received CAN messages based on the PID structure to extract the data.

-

What are some example projects using STM32 CAN OBD2?

- Custom diagnostic tools, data loggers, performance monitors, and custom dashboards are just a few examples.

-

What software tools are needed for STM32 CAN OBD2 development?

- STM32CubeIDE or similar IDEs, along with a CAN bus analyzer for debugging are commonly used.

For support, contact WhatsApp: +1(641)206-8880, Email: [email protected] or visit us at 789 Elm Street, San Francisco, CA 94102, USA. We have a 24/7 customer support team.